What is an Explosive Atmosphere?

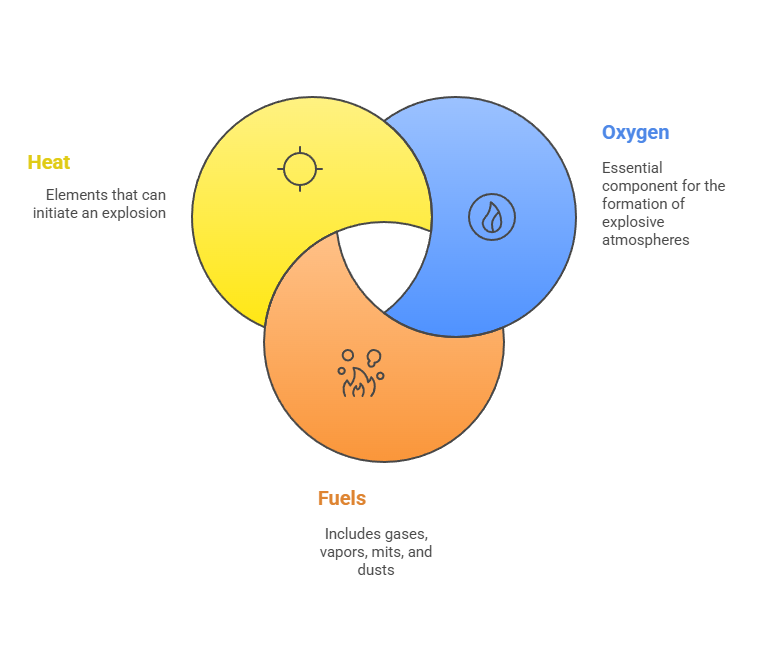

An explosive atmosphere is defined as a mixture of air with flammable substances (gases, vapors, mists, or dusts) which, under normal conditions of pressure and temperature, can ignite upon contact with an ignition source. This mixture contains a sufficient concentration of the flammable substance in the air to propagate rapidly in the form of an explosion.

Explosive atmospheres are present in many industrial environments, both from gaseous substances and airborne particles. They represent a significant hazard due to the energy released during an explosion, which can cause severe damage to equipment, facilities, and personnel.

Types of Substances That Can Generate Explosive Atmospheres

Flammable Gases and Vapors

- Light hydrocarbons: such as methane, propane, or butane. Common in the oil, gas, and chemical sectors.

- Alcohols and solvents: such as ethanol, acetone, or toluene. Common in cleaning processes, manufacturing, and pharmaceuticals.

- Hydrogen: used in ammonia production, refineries, and fuel cells. Its high diffusion and low ignition energy make it a critical element in ATEX assessments.Its low molecular weight and high diffusion ability allow it to accumulate in confined spaces, creating explosive atmospheres even at low concentrations (lower explosive limit: 4% by volume).

- Light hydrocarbons: such as methane, propane, or butane. Common in the oil, gas, and chemical sectors.

Vapors from Thermal Oils

Thermal oils, used as heat transfer fluids in petrochemical, power generation, and industrial heating industries, can emit flammable vapors under certain conditions. When mixed with air, these vapors can form explosive atmospheres, especially where autoignition temperatures are exceeded or ventilation is insufficient.Combustible Dusts

- Organic: such as flour, sugar, wood, or coal.

- Metallic: such as aluminum, magnesium, or titanium. These pose a high risk due to their reactivity and ability to form flammable airborne clouds.

- Organic: such as flour, sugar, wood, or coal.

Flammable Mists

These can form from the dispersion of flammable liquids (oils, fuels) as fine droplets suspended in air.

Classification of Explosive Atmospheres

Classification is based on the frequency and duration of the presence of flammable substances in the environment. The ATEX directive defines specific zones to identify the level of risk:

Gases, Vapors, and Hydrogen

- Zone 0: Continuous or prolonged presence of an explosive atmosphere. Example: inside fuel storage tanks.

- Zone 1: Likely presence under normal operating conditions. Example: near valves or leaks in transfer systems.

- Zone 2: Unlikely and short-term presence. Example: areas adjacent to occasional leak points.

Combustible Dusts

- Zone 20: Continuous or frequent presence of combustible dust in suspension. Example: inside grain silos.

- Zone 21: Occasional presence during normal operations. Example: areas near milling equipment.

- Zone 22: Unlikely and brief presence. Example: areas with sporadic dust accumulation.

Key Parameters for an ATEX Study

An ATEX study helps identify and manage risks related to explosive atmospheres. Key parameters to consider include:

- Identification of release sources: Locating leak points, releases, or accumulations of flammable substances.

- Substance characteristics: Determining properties such as flammability limits, autoignition temperature, and minimum ignition energy.

- ATEX zone classification: Defining hazardous zones based on the frequency and duration of explosive atmosphere presence.

- Calculation of hazardous distances: Delimiting areas based on dispersion and possible ignition sources.

- Ignition source evaluation: Identifying elements capable of triggering an explosion (sparks, static electricity, hot surfaces, etc.).

Conclusion

Controlling explosive atmospheres is a critical aspect of industrial safety management. Proper identification of flammable substances, accurate classification of zones in accordance with ATEX regulations, and thorough evaluation of ignition sources can prevent incidents with potentially catastrophic consequences.

Implementing protective measures, combined with a detailed technical risk analysis, is essential to ensure the integrity of facilities and the safety of personnel. A preventive approach—based on data and current regulations—is the best strategy to minimize the probability and impact of an explosion in industrial environments.