Pinch Analysis is a widely used energy integration methodology aimed at optimizing heat usage in industrial processes. Since its initial development in the 1970s by Bodo Linnhoff, this technique has significantly evolved into a comprehensive approach for process improvement, resource management, and sustainability.

Below is an overview of its fundamentals, key tools, applications, and the most recent scientific advancements.

What is Pinch Analysis?

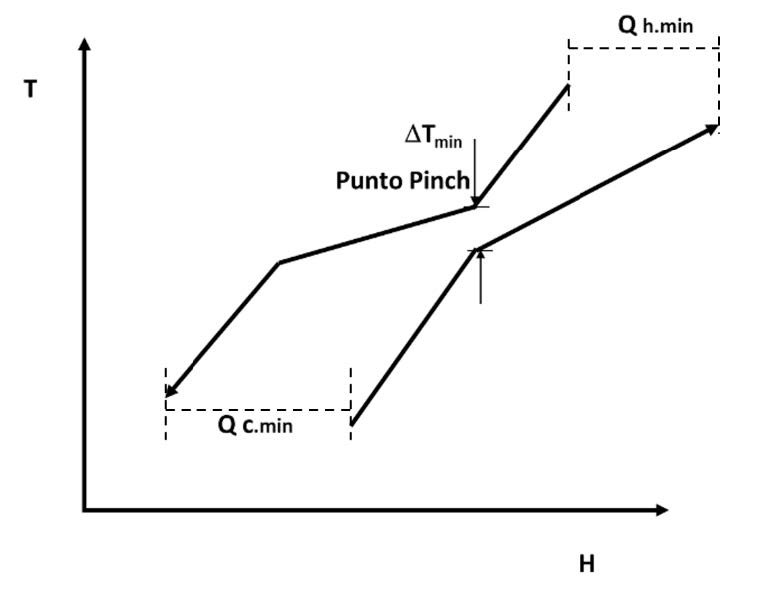

Pinch Analysis is a methodology based on thermodynamic principles that seeks to minimize the consumption of external utilities (such as steam, water, and fuels) and the costs associated with the design and operation of heat exchangers. Its core lies in identifying the Pinch Point, defined as the minimum thermal gap (ΔTmin) between the hot and cold streams of a process. This point determines the minimum heating and cooling demands, enabling the design of optimal heat exchanger networks. The analysis involves two key tools:

- Composite Curves: Graphically represent hot and cold streams on a temperature vs. heat load diagram, making it possible to visualize heat surpluses and deficits within the process.

- Problem Table: A numerical method that divides temperature intervals to calculate heat balances and estimate minimum utility requirements through a thermal cascade approach.

Establishing Energy Targets

The first step in Pinch Analysis is determining the process’s minimum energy requirements. Hot streams (to be cooled) and cold streams (to be heated) are represented on a temperature–enthalpy diagram. The closest point between the composite curves defines the Pinch Point, dividing the system into two zones:

Source: https://blogs.ugto.mx/rea/clase-digital-5-consumo-minimo-de-energia-en-un-proceso-industrial/

- Above the Pinch: Additional heat is required.

- Below the Pinch: Excess heat is generated.

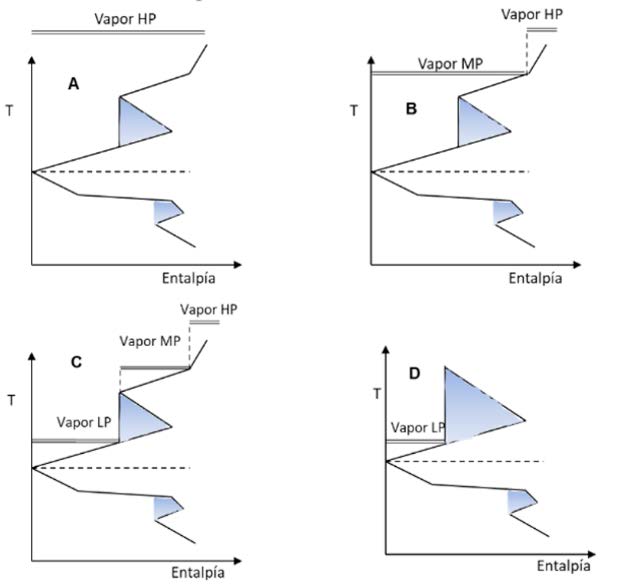

Source: https://blogs.ugto.mx/rea/clase-digital-13-seleccion-de-servicios-auxiliares/

For a more detailed analysis, the Grand Composite Curve is used. This tool considers heat balances across temperature intervals and identifies:

- The total amount of energy required.

- The temperature levels at which energy is needed.

- Opportunities to utilize surplus heat through internal thermal cascades.

The Grand Composite Curve also optimizes the amount and quality of energy services, ensuring efficient heat transfer with a minimal ΔTmin gradient.

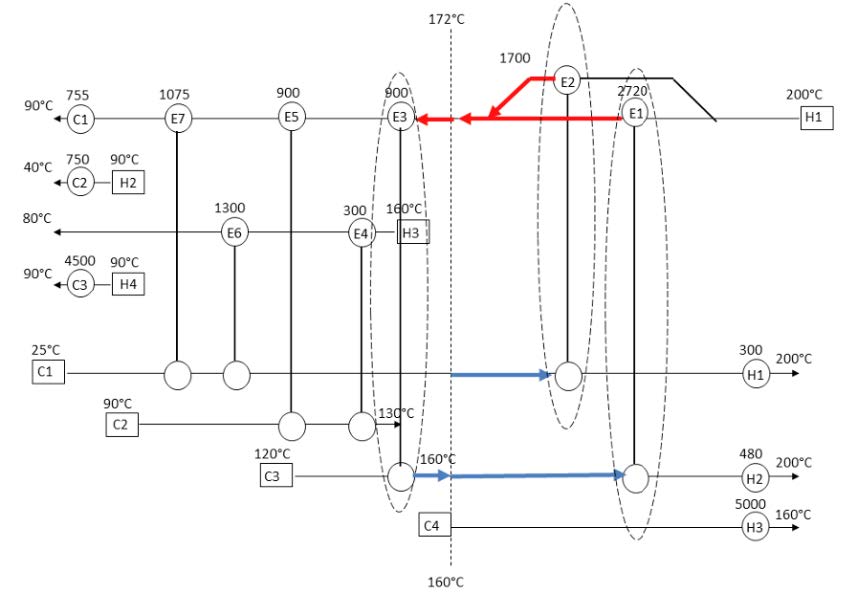

Heat Exchanger Network (HEN) Design

Source: https://blogs.ugto.mx/rea/clase-digital-7-diseno-de-redes-de-recuperacion-de-calor/

The design of heat exchanger networks (HEN) is the core of the Pinch methodology. These networks maximize heat recovery between process streams, reducing the need for external utilities like steam or cooling water. The fundamental design rules are:

- Do not use utilities to cool streams above the Pinch.

- Do not use utilities to heat streams below the Pinch.

- Do not transfer heat between streams separated by the Pinch.

These rules ensure a thermally efficient system and significantly reduce operating and capital costs.

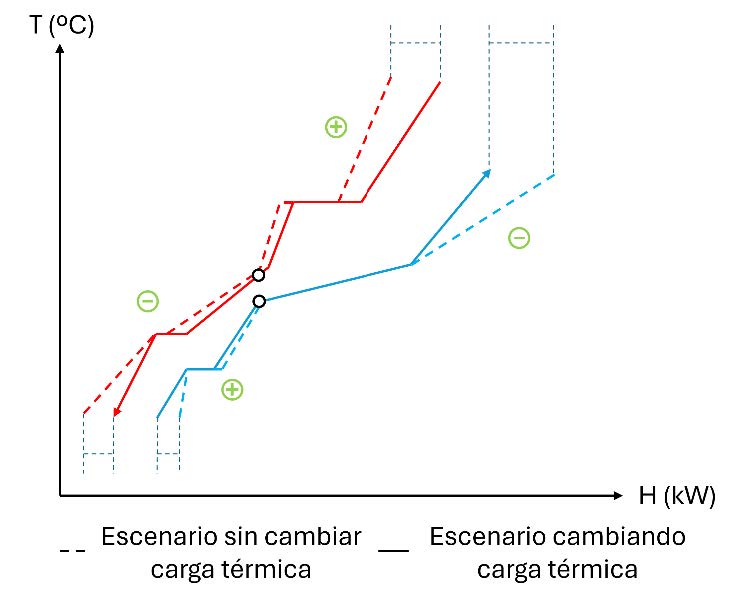

Process Modification: The Plus-Minus Principle

The plus-minus principle describes how changes in energy and mass within a process affect its energy efficiency:

- Above the Pinch: Increasing heat load in hot streams or decreasing it in cold streams reduces the need for heating utilities.

- Below the Pinch: Reducing heat load in hot streams or increasing it in cold streams reduces the need for cooling utilities.

In addition, adjusting stream temperatures can improve overall process efficiency, enhance thermal management, and reduce energy targets.

Applications and Benefits

The Pinch methodology has been successfully applied in industrial sectors such as refineries, petrochemicals, steel production, distillation plants, paper mills, and breweries. Its benefits include:

- Reduced energy consumption: Through thermal integration and minimized utility usage.

- Cost savings: Operational, capital, and environmental costs are lowered.

- Design flexibility: Applicable to both new plants and the retrofitting of existing facilities.

- Environmental sustainability: Reduction of greenhouse gas emissions and optimized use of resources like water and energy.

Future Perspectives

The Pinch methodology will continue to play a key role in the transition to more sustainable industrial processes. Future development areas include:

- Integration of renewable energy sources, such as solar and wind, into industrial processes.

- Digitalization and automation using artificial intelligence to improve design and operations.

- Incorporation of circular economy principles to close material and energy loops, reducing waste and emissions.

Scientific Advances and State of the Art in Pinch Analysis

Pinch methodology has evolved from a tool focused solely on energy optimization to a comprehensive approach that promotes industrial sustainability. This evolution has enabled its application in key areas, addressing environmental, economic, and operational challenges with innovative and flexible solutions.

In the area of environmental footprints, Pinch Analysis has incorporated tools like Carbon Emission Pinch Analysis (CEPA), which assesses and reduces the impact associated with carbon, water, and other environmental indicators. These innovations are essential to meet international environmental standards and mitigate the global trade impacts on industrial sustainability. Additionally, the methodology now includes water-energy nexus analysis, optimizing the simultaneous use of these resources in industrial processes—critical in the face of increasing water scarcity and energy demand.

Regarding renewable energy and biofuels, the methodology has integrated technologies such as supercritical gasification, hybrid energy production, and hydropower storage systems. These solutions have not only improved energy efficiency but also reduced emissions associated with industrial processes. Another significant advancement is the optimization of biomass supply chains, maximizing resource use and ensuring regional sustainability. Planning tools like RegiOpt have facilitated the design of sustainable energy networks tailored to local conditions, enhancing decision-making at both regional and industrial levels. Additionally, the integration of isolated systems and combined first- and second-generation ethanol production has proven to be an effective solution for regions with limited access to conventional resources.

Through these innovations, Pinch Analysis addresses not only energy efficiency but also integrates advanced technologies and planning tools, consolidating its role as a key methodology in the transition toward more sustainable industrial processes.

Conclusion

Pinch Analysis has gone beyond its initial focus on energy optimization to become a comprehensive tool for resource management and sustainability in process engineering. From cost and emissions reduction to the integration of emerging technologies, this methodology remains a cornerstone in the development of more efficient and environmentally responsible industrial solutions. With continued innovation and adaptation to changing needs, Pinch Analysis will continue to lead the way toward a more sustainable industrial future.