The relevance of solar structures is growing in the investment of PV solar plants due to many factors related to the PV market evolution: tendency towards multi-Megawatt plants, global increased of the competition and new emerging markets, and overall drastic drop of prices on solar panels.

CADE occupies a privileged position in the PV sector thanks to its broad experience, as a reference in the development, advisory and design engineering services throughout the value chain of solar PV, including integrity assessment projects for existing plants.

CADE counts most of the industry’s key players among its clients: developers, investors, insurance companies, EPC contractors, manufacturers, plant operators, maintenance companies and plant owners.

Our engineering services stand out in terms of competitiveness and reliability because of our deep knowledge of the product, use of sophisticated design-analysis tools and methodologies, and extensive experience in the development and validation of fixed and mobile PV structures (1 and 2 axles).

CADE provides all Product Development Phases: from conceptual design, structural simulation, detailed design and definition of manufacturing and assembly processes, to operation and maintenance, where we offer specialised engineering and consultancy services for structural integrity.

Design and Analysis

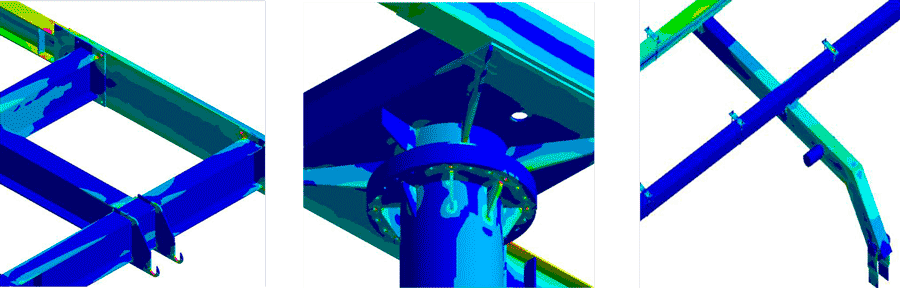

By means of advanced engineering calculation tools and finite element analysis (FEA), we can obtain detailed models of diverse types of structures to evaluate and analyse its global and local behaviour. The aim is to reduce the structure weight while guaranteeing the structure security and reliability. Through finite element simulations, it is possible to evaluate in detail critical elements of the structure (profiles, welds, bolted joints, anchors, etc.) as well as to define failure modes that could not be analysed with other calculation methods (buckling, large displacements, nonlinearities, etc.).

CADE incorporates complex analyses related to failure prediction, reliability and availability (FMEA, FMECA, RAM, etc.) within its working methods for PV structures. This methodologies are commonly applied in sectors where manufacturing requirements are extremely demanding.

Wind Tunnel Testing

The advanced knowledge of international design standards and codes, concerning loads on structures, allows us to determine the unfavorable load types on each element of the structure. However, conducted researches have revealed that the wind loads determined by standards and codes generally consider too conservative safety margins that may imply additional costs.

By means of a wind tunnel test, we can define accurate wind loads that should be taken into consideration, obtaining more precise and specific calculation models for each location.

CADE has an extensive experience in selecting specialized international laboratories, defining and supervising wind tunnel tests, as well as post-processing and analysing the results of these tests.

Actuators and Driving Devices

In structures with solar trackers, the right selection of the drive system has a great relevance in terms of manufacturing costs, availability of operation and reliability. CADE selects, designs and validates the most appropriate drive system according to the objective costs and specific structural requirements of the project, also taking into consideration the operation and maintenance conditions related to the service life of the structure.

Foundations and Anchorage systems

The right foundation or anchorage systems (concrete foundations, micropiles, structure pillar stuck in the ground, etc.) needed to set the structure into the ground may also incur an important percentage of the final cost of the structure. It should be considered as a relevant component, not only in terms of material, but also in terms of construction and assembly times.

Design to cost, Lean Manufacturing and Supply Chain

Cost reduction is not only linked structural material reduction. The elaboration of a design focused on an unexpensive, flexible and mass-produced product should consider all possible process variables.

CADE’s experience in the design of singular structures, the use of simulation tools and the deep knowledge of industrial assembly processes, allows as us adapt the design to the production capacities of manufacturers and clients.

Defining a manufacturing process based on lean manufacturing according to the current trends implies a cost reduction which affects directly the total structural cost.

Further information:

For any question or further information request about our services and PV structures, please complete the following form: