We Define and Ensure an

Integrated Welding Process Design

Identifying welding issues in industrial engineering projects to improve durability and reliability.

Welding Consulting

We define and ensure the quality, safety, and efficiency of welding processes in industrial and advanced engineering projects.

Our comprehensive approach covers everything from failure analysis to the full review of welding procedures and project documentation, ensuring compliance with the most demanding technical standards while optimizing resources and outcomes.

Whether tackling complex challenges in large-scale infrastructure projects or improving processes in manufacturing environments, we are committed to delivering solutions tailored to the real needs of each project.

Welding Failure Analysis

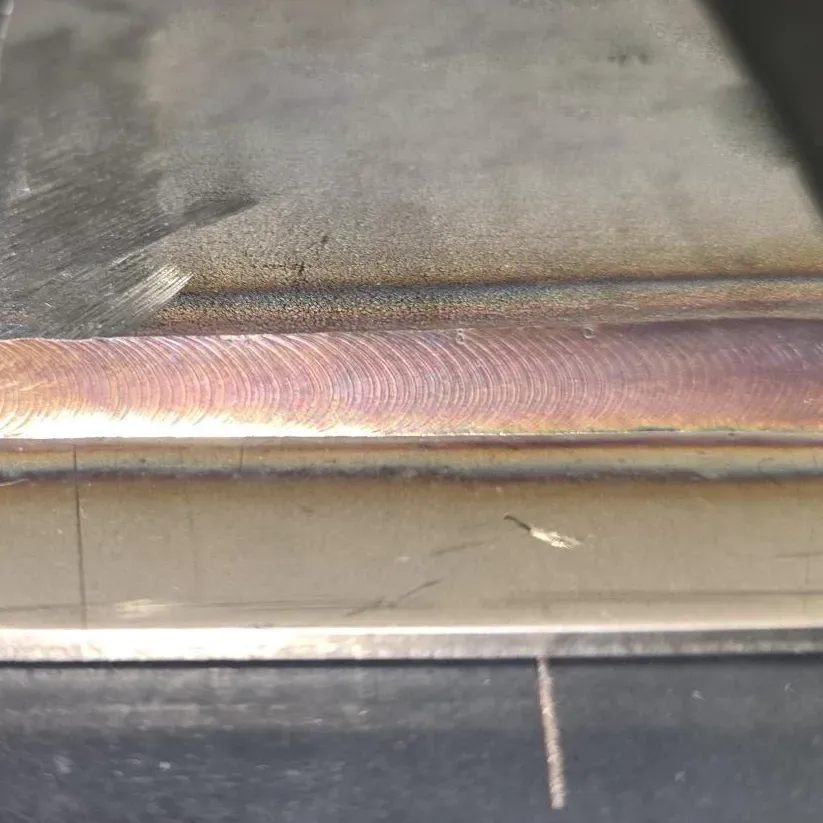

We have a team of welding engineers specialized in conducting thorough failure investigations to identify root causes of issues in welded joints. This service includes:

Detailed evaluation of welds and procedures

Analysis of operating conditions and materials used

Technical solutions to improve weld durability and reliability

Our failure analysis follows a systematic methodology using advanced diagnostic tools and techniques, providing critical insights into weld performance. We also offer actionable recommendations aligned with industry best practices and standards.

Benefits of Failure Analysis:

Accurate identification of underlying issues

Development of corrective and preventive actions to optimize structural integrity

Reduced repair and maintenance costs by improving operational efficiency

Prevention of recurrence by addressing systemic problems

Comprehensive Review of Welding Projects

Our consulting includes an exhaustive review of all welding process stages, focused on ensuring regulatory compliance and execution excellence.

Key Areas of Evaluation:

Procedure Qualification: We verify that welding procedures comply with project specs and applicable standards such as ASME BPVC, EN ISO 15614-1, and PED (2014/68/EU)

Welder and Operator Qualification: We assess technical competencies to ensure weld quality and compliance

Filler Materials: We review compatibility and properties of welding consumables

Preheat and Postheat Practices: We supervise techniques to reduce residual stresses and avoid defects

Post-Weld Heat Treatment (PWHT): We validate procedures to ensure structural integrity and long-term performance

We emphasize client collaboration to ensure all welding processes are optimized and aligned with project goals.

Benefits of Comprehensive Review:

Full compliance with international standards and quality regulations

Improved weld reliability and longevity

Risk mitigation during execution and optimized operational results

Detailed documentation to support audits and project certification

Review of

Methods, Capabilities, and Testing Results

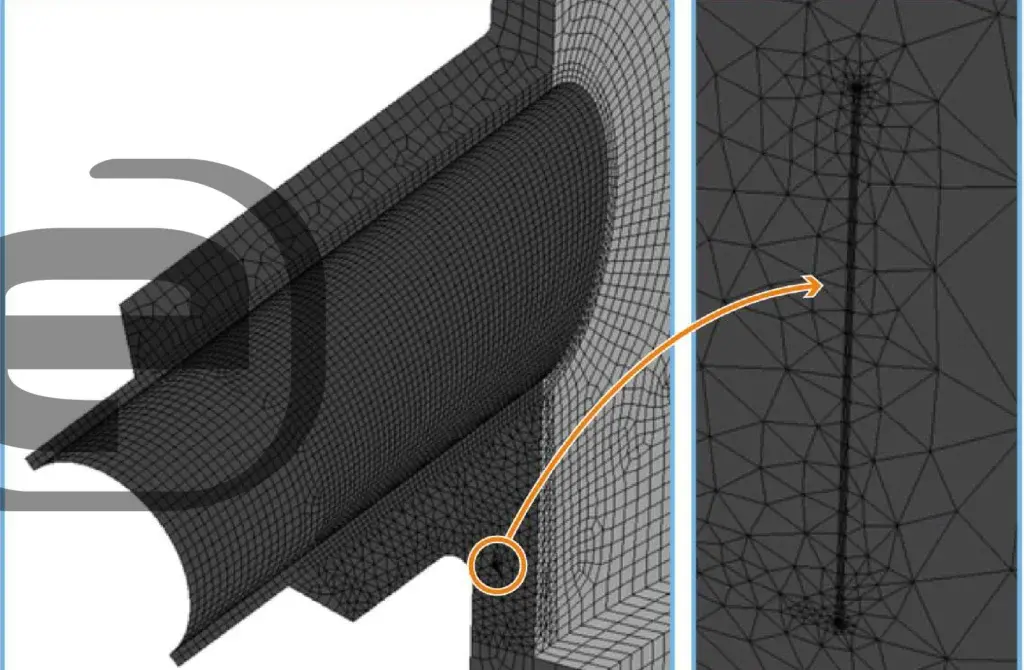

We perform a thorough evaluation of both destructive and non-destructive testing (NDT) methods, assessing procedures and results to ensure compliance with project requirements.

Types of Tests Reviewed:

Non-Destructive Testing (NDT): includes visual inspection, ultrasonic testing, radiography, and magnetic particle testing to ensure joint integrity without damaging the welds

Destructive Testing: includes tensile, hardness, and impact testing to provide essential data on weld mechanical properties

Our evaluations rely on advanced testing technologies and recognized international standards, ensuring result reliability.

Benefits of Test Review:

Guaranteed quality and reliability through verified testing methods

Early detection of potential defects or inconsistencies

Increased project confidence, supported by detailed test reports