The owner of a steel plant in DURGAPUR (India) requested CADE to assess the remaining life and mechanical integrity of eight gas piping systems in a power generation cycle (60MVW), including the evaluation of hanger/support points and equipment terminal connections as well.

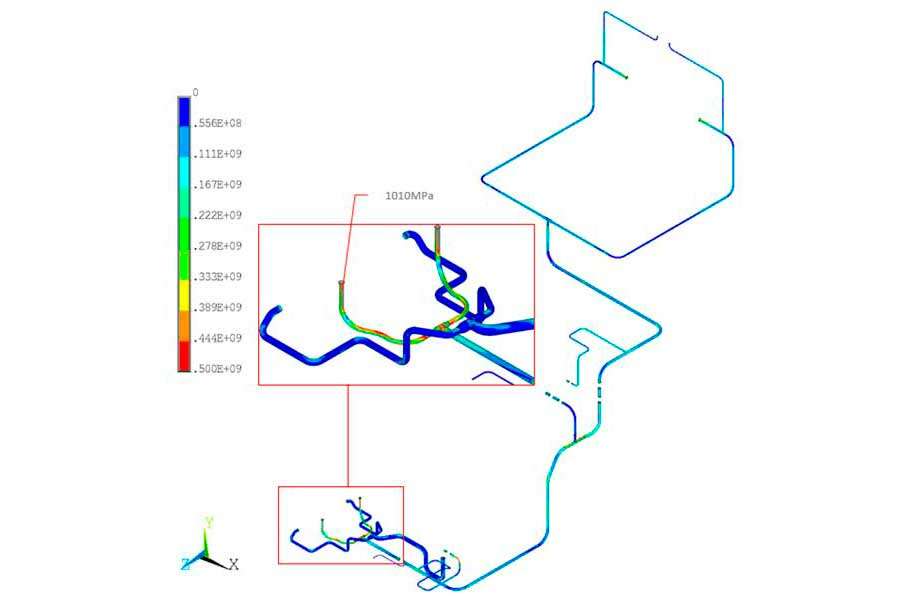

For this purpose, both flexibility analysis and subsequent stress analysis were performed in order to validate the following failure modes: plastic collapse, ratcheting and creep-fatigue. Other identified issues such as corrosion, ovalizations-deformations and cracks, directly related to the plant aging, were considered on this evaluation.

In order to precisely simulate actual conditions of the systems, a strain hardening material model was considered in creep analysis to implement creep strains effect. Moreover, inelastic properties of the material (plasticity) were also taken into consideration, defining such properties as variables based on temperature.

Creep damage assessment was performed according to the API 579-1/ASME FFS-1 by means of Finite Element Analysis (FEA). The analysis sequence included:

Results of analysis allowed to determine the accumulated damage due to creep-fatigue effect along cyclic operational history of the plant, as well as the remaining life of the piping systems evaluated for current operating conditions.

CADE provides advanced engineering, simulation and consulting services for critical equipment, piping systems or structures when they are not operating as expected, when a mechanical or structural failure occurs, or when it is necessary to evaluate its mechanical integrity and remaining life.

For any further information , please complete the following form:

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

If you please, contact us and tell us about your project to inform you what we can do for you

We inform you about our engineering solutions