Pressure vessel – Courtesy of GRIRO Romania

ASME codes (American Society of Mechanical Engineers) regulates boilers and pressure vessels design, development and construction in a wide range of industries worldwide.

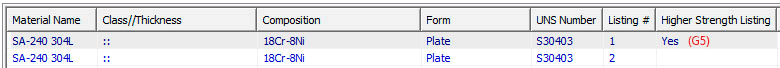

When selecting materials, in some cases such as the following, ASME II Part D can provide different mechanical properties for the same type of material. For example, for 304L grade stainless steel plate, ASME II Part D provides two rows of stress properties to identify SA-240 304L stainless steel in low and high strength. The difference between the two is that one of these materials (the one identified with G5 note*) has better mechanical properties than its counterpart.

*G5 note indicates that allowable strength of the material is set above the customary 66% yield point.

The main benefit of using G5 stainless steel in the design of components under pressure is that it requires less material thickness than the stainless steel without G5 note. For the same and particular design conditions (pressure and temperature), using the two materials indicated in the previous table, there would be a difference of 12 mm in the wall thickness required in the pressure calculation of the internal pressure of a shell ring.

However, ASME II Part D advises against using materials identified with Note G5 for the design of body flanges to be used in bolted joints or other applications where small amounts of distortion may cause leaks or malfunctioning.

Experience

Further information:

For any question or further information request about boilers and/or pressure vessel design, development and construction, please complete the following form: