Industrial processes, unlike the tertiary and residential sectors, require a higher proportion of heat than electricity. For this reason, the integration of renewable energies in these processes must consider thermal components that replace fossil generation systems.

In this sense, different ways of obtaining renewable heat arise:

- Through biomass

- Through solar thermal energy

- Through renewable photovoltaic or wind electricity.

Biomass is a good option if we have a reliable and cheap supply. However, this cannot be extrapolated to all types of industry and, ultimately, the fossil dependency is replaced by another dependency, biomass, over which we have no control.

Solar thermal energy is a very interesting option, especially with thermal storage, since it allows energy independence to be gained when it comes to generating heat, both in its simple and concentrated forms. Its advantages have already been listed in another article on this website: “Thermal solar energy is here to stay.”

Therefore, we can say that it is the turn of the generation of heat through renewable electricity, which can be achieved through photovoltaic and wind power either by local or remote generation. Generally, for purely economic reasons, the electricity generated is consumed first by the electrical equipment of the factory, and the surplus is used to generate heat that is injected into the process.

In this article, we will deal with photovoltaics as a source of generation thanks to its adaptability to roofs and the ground, as well as its competitive levelized cost of energy.

Content

Barriers to the increase in renewable electricity penetration

The fact that renewable energy sources are intermittent is not a big secret: we get electricity and heat when there is sun or wind, just as we depend on daily and seasonal weather conditions.

This apparent lack of manageability is the preferred argument of critics of clean energy to justify the stability offered by other energies such as fossil (more flexible) and nuclear (more stable).

To this handicap, and if we are talking about electrification of processes from remote generation, some additional factors are added:

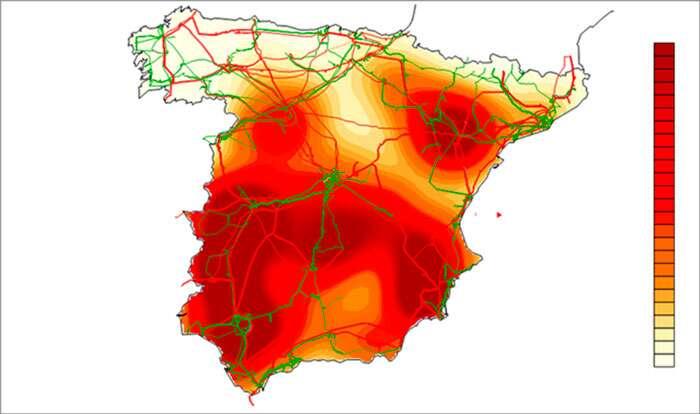

- When it comes to Spain, according to Red Eléctrica (Spanish electricity network regulator), some nodes in the network are saturated, so the connection of new photovoltaic and wind installations, as well as their discharge to the network, cannot be guaranteed on a regular basis.

- The Administrations do not end up promoting all forms of energy storage with the exception of electric batteries whose investment for mass storage is still high in industrial environments.

- The processing of renewable electricity projects by the central and regional governments is not agile, reaching the point that the expiration dates of many of the guarantees granted to development companies are approaching.

In short, it is not possible to take full advantage of the potential of both installed and projected renewable capacity for technical and, above all, administrative reasons.

The proximity energy generation and thermal storage as a solution

These barriers can be partly or totally overcome by approaching the problem from two different points of view; On the one hand, it is necessary to bring generation closer to consumption and, on the other, to manage surplus energy over time. There are alternatives for this:

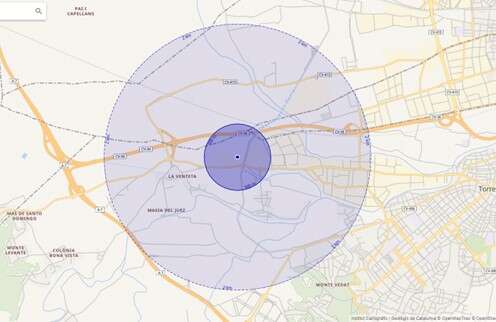

- Bring the photovoltaic generating installation closer to the consumer, or what is the same, to our factory or process. For this, there are different formulas such as using the roofs of own warehouses, buying or renting adjacent land or exploring the new formulas given by the revision of Real Decreto Ley 18/2022 (in Spanish) that allows installing a photovoltaic field up to 2 km from the point of consumption without having to having to carry out long bureaucratic procedures or having to deal with technical problems of Red Eléctrica.

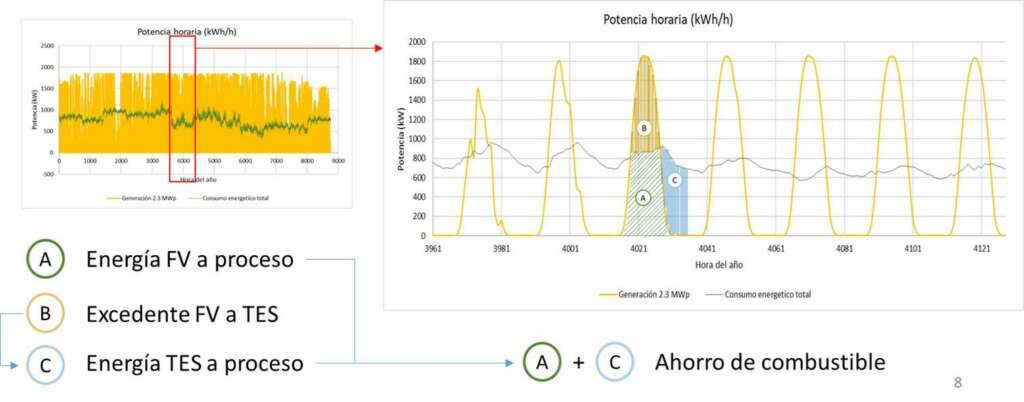

- Use thermal storage systems (also called TES) that make it possible to oversize the photovoltaic installations for our factory, manage surpluses by pouring them into the process at another time and, consequently, increase global renewable coverage, both electrical and thermal.

Advantages of electrification and thermal storage in processes

Thanks to the combination of electrical heat generation equipment such as boilers, generators and electrical resistances with thermal storage systems, it is possible:

- Increase the value of electrical surpluses, since:

- Most of the surpluses are self-consumed in the process in the form of heat, which has two advantages: (1) they are not sold to the electricity network at a price imposed by the electricity companies or the electricity pool, (2) Becoming an energy exporter is optional in the amortization of your installation.

- Increases the energy independence of the process, saving on fossil fuel costs and eliminating uncertainty of production cost.

- Defer the moment of purchase from the moment of consumption:

- Thermal storage systems are capable of charging at will. In other words, they can be charged with other energy sources such as network electricity at times when the price is competitive to release the heat to production later. This strategy will increase in importance as renewable capacity increases in the coming years.

Conclusions: Extending the limits of renewable coverage in our process

Electrification plus thermal storage allows the direct generation of electricity and heat simultaneously and the release of heat in a deferred manner. This makes it possible to increase the renewable penetration in the processes in a significant way.

Although it is true that each process has its singularities and each case deserves to be studied, electrification plus storage reaches its maximum performance when it is coupled to daily processes and with a not very pronounced seasonality.

For example, applying this strategy to a 24/7 food industry process with low seasonality makes it possible to cover 35-45% of the electricity demand and 60-85% of the thermal demand with attractive returns on investment and levelized energy costs. without applying aid or subsidies. The sale of the remaining electrical capacity after its thermal use is not included either, but it allows to improve the return if the industry decides to export it to the network.

CADE will help you improve your energy Independence

The integration of renewable energies in industrial processes in which heat is involved requires specific know-how, making it essential to have companies specialized in industrial renewable integration. In this way, the renewable installation is specified from the beginning in an optimized way, which increases its return and reduces the risk in any of the scenarios.

CADE, thanks to its notable expertise in the integration of renewable technologies in industrial processes, offers comprehensive support to the client through all phases of this process (integration analysis, technology selection, feasibility analysis, conceptual design, basic and detail, purchases and construction and commissioning) being able to perform different roles, either as property engineering, developer of “turnkey” projects (EPC) or supplier of thermal generation and storage equipment using its own technology.

Further information

For any query or request for additional information about our services and technologies, please complete the following form: