The key to a 100% renewable industry

The solidTES storage solution allows greater coverage for renewable energy generation systems and provides flexibility in energy management.

solidTES makes it possible to smartly manage a variable energy mix (electrical and thermal) on demand, offering renewable coverage of up to 100%. The integrated and decarbonized solution that allows energy independence from fossil sources.

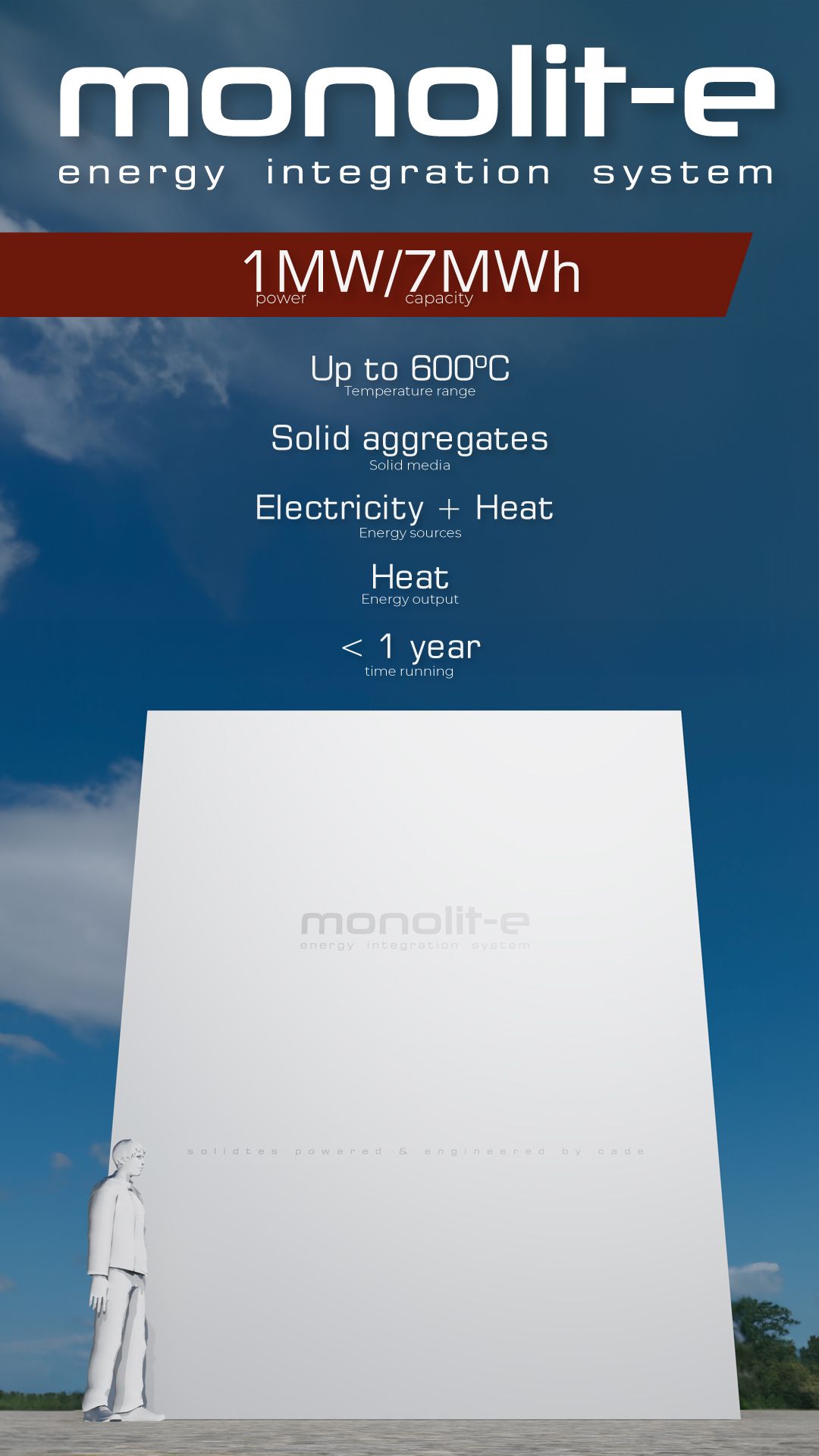

Power Capacity

Temperature Range

Solid media

Energy Sources

Energy Output

Availability

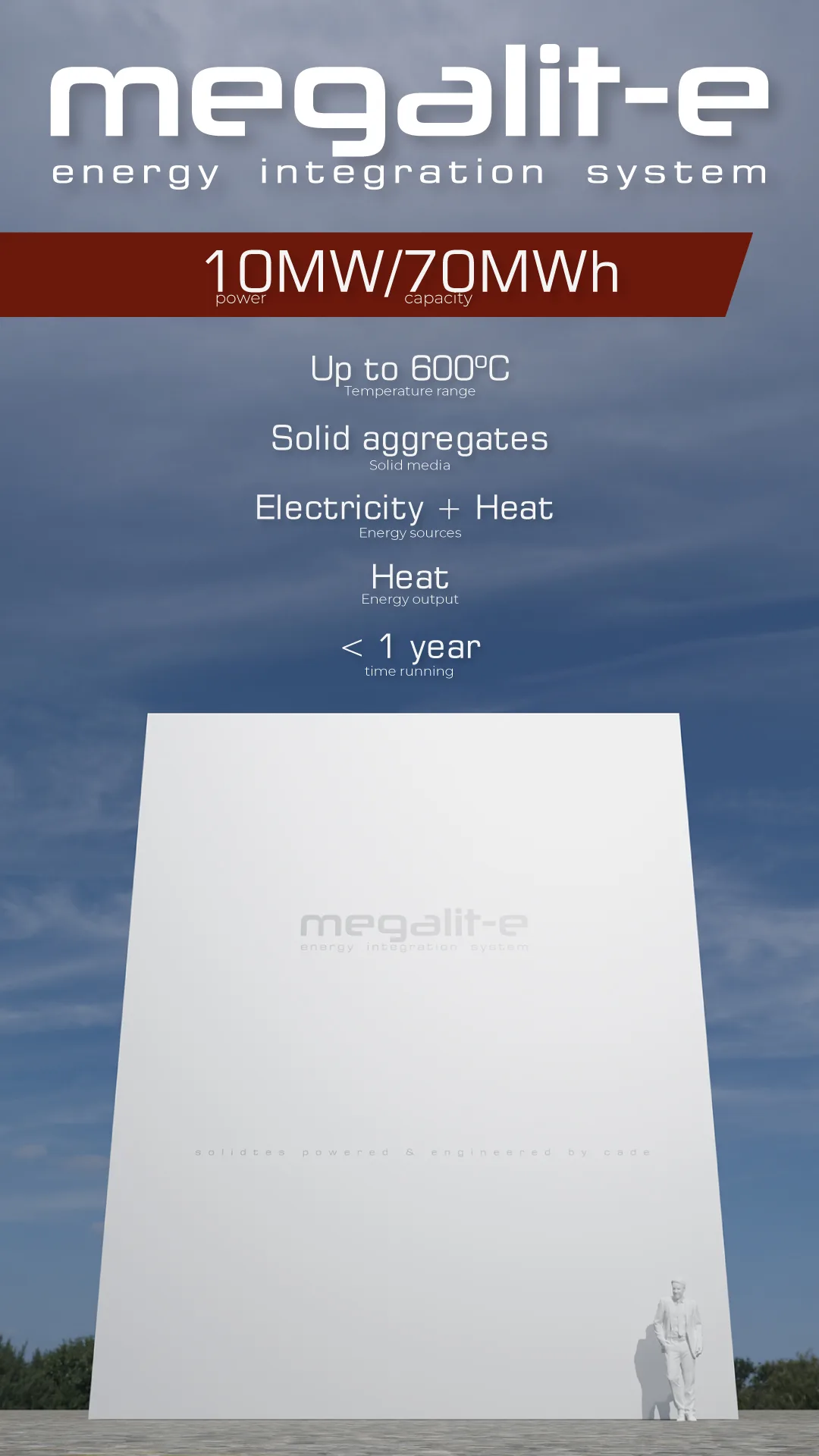

Power Capacity

Temperature Range

Solid media

Energy Sources

Energy Output

Availability

Monolit-e, located at “Factoria CADE”, is a demonstration system capable of storing up to 400 kWh of energy in the form of heat from an electrical source of up to 75 kW.

Monolit-e is designed in a modular way, allowing CADE to conduct experiments of diverse nature, involving different storage materials, transfer powers, and storage capacities.

Thanks to this prototype, it is possible to simulate a wide variety of scenarios, with data being recorded in real time. Subsequent analysis enables the validation of design hypotheses or process considerations, ensuring a robust system scalability.

solidTES is the center on which it is possible to integrate a variable generation mix, allowing the total management of the energy supply to the industry. It is the key technology to have an integrated and intelligent system to achieve 100% renewable coverage in the industry.

Related articles

1st Gen SolidTES

Demonstration plant with a prototype thermal storage system based on solidTES technology, utilizing thermosolar charging to supply steam for a process. (Kean Soft Drinks Ltd. Limassol, Cyprus).

This 1st Gen solidTES storage system is based on a simple concept of thermal energy storage using a bundle of tubes (through which a high-temperature thermal fluid circulates) embedded in a matrix of high thermal performance composite material (similar to concrete), with its composition varying according to the required operational temperature range (up to 400°C).

This system is capable of operating with different heat transfer fluids, such as molten salts, thermal oil, pressurized water, steam, or air, derived from renewable or conventional energy sources.

In 2018, as part of the EDITOR Project (Funded by European funds through SOLAR-ERA.NET), CADE launched a concrete thermal storage system consisting of two containers with a capacity of 600 kWh, capable of storing thermal energy generated in a concentrating solar field and releasing that energy at a later time to generate process steam. As of August 2023, the EDITOR TES has operated successfully, continuously, and without incidents in its operation and maintenance (O&M).

| TES Project EDITOR (Limassol, Cyprus) Production plant for KEAN Soft Drinks, Ltd | Demonstration plant with a prototype thermal storage system based on solidTES technology with thermosolar charging. |

| Status | In operation since 2018 |

| Power | 125 kW th |

| Storage Capacity | 600 kWh th |

| Coupled Generation Technology | Concentration solar using HTF |

| Maximum Operating Temperature | 400 ºC |

| Storage Material | Thermal concrete matrix |

| Dimensions / Configuration | 2 x 20-ft containers |

| Discharge | Heat with Siliconized Thermal Oil at 400ºC and renewable steam generation |

| Heat Exchanger | Bundle of carbon steel tubes embedded in storage material |

2nd Gen SolidTES

Demostration plant with a prototype thermal storage system based on solidTES technology, utilizing thermosolar charging for trigeneration. (Lavrio, Greece).

The European project TES4Trig, initiated in 2021, allowed CADE to continue innovating in its solidTES thermal storage technology program.

The second-generation solidTES, capable of handling temperatures up to 400 ºC, is based on aggregates as the heat storage material and air as the heat transfer fluid.

The configuration of the second-generation solidTES is based on a monolith composed of several modules that encapsulate the storage material. Hot and cold air is circulated through these modules to charge or discharge the TES.

This increased modularity facilitates construction and assembly, significantly reducing its costs.

The system developed by CADE for the TES4Trig Project is based on this technology and is designed to work with a solar field of parabolic trough collectors that use Silicone-based Mineral Oil as the thermal fluid. The TES absorbs surplus generation from this field and subsequently supplies it to an organic Rankine cycle capable of providing electricity, cooling, and heating to an office building (trigeneration).

| TES in TES4trig Project. (Lavrio, Greece) | Demonstration plant with a prototype thermal storage system based on solidTES technology with thermosolar charging |

|---|---|

| Status | In operation 2023 |

| Power | 75 kW th |

| Storage Capacity | 400 kWh th |

| Coupled Generation Technology | Concentration solar using silicone-based thermal oil (HTF) |

| Maximum Operating Temperature | 400 ºC |

| Storage Material | Structured Selected Mineral Aggregates |

| Configuration | Monolith |

| Discharge | Heat with 400ºC thermal oil Renewable trigeneration system (heat, cooling, and electricity) |

| Dimensions | (5×2.5×6) m |

| Heat Exchanger | HTF-Air Heat Exchanger |

3rd Gen SolidTES

(*) Experimental prototype system “Monolit-e ” for thermal storage based on solidTES technology, located at CADE Factory, Albacete, Spain.

The third-generation solidTES is CADE’s response to the new energy paradigm, where the combination of renewable energy sources is necessary to achieve complete decarbonization of the industry.

This new evolution (3rd-gen), built upon the foundations of the TES4TRIG project and the design of the second-generation solidTES, implements electrical charging capacity, improving in terms of capacity per unit of volume (as it can handle temperatures up to 600ºC) and versatility for integration into different configurations of renewable generation/electrification and heat demand. This generation allows solidTES to become a key component in projecting a 100% renewable industry in the short term.

This approach enables the integration of various energy sources of different nature, such as concentrated solar thermal, photovoltaic, wind, or the electric grid, among others, configuring an energy mix that can be optimally managed according to demand using thermal energy, which is transferred to or from the thermal energy storage (TES) system.

The third-generation solidTES features an intelligent control system based on a machine learning algorithm that manages energy according to process and customer needs. Utilizing the Internet of Things (IoT), authorized personnel can easily access the system, visualize real-time data, change preferences, or give commands.

The Monolit-e and Megalit-e systems, based on this technology, are specified and optimized to absorb electrical energy and release it as heat to the process as needed. Each model covers different power and capacity ranges, and one or the other is applied based on the magnitude and requirements of the process demand.

CADE has a prototype, operational since 2023, of the Monolit-e system at its innovation center in Albacete, Spain (CADE Factory). The facilities and equipment available at the CADE Factory have the fundamental goal of testing and validating prototypes for the development of industrial-scale implementations with guarantees.

| Prototype Monolit-e (*) | Monolit-e | Megalit-e | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Status | In operation 2023 | Pipeline 2024 | Pipeline 2024 | ||||||

| Power | 100kW – 300kW | 0.5 – 2 MW | 3 – 10 MW | ||||||

| Storage Capacity | 400kWh – 1500kWh | 3.5 – 28 MWh | 21 – 70 MWh | ||||||

| Coupled Generation Technology | Electricity | Electricity | Electricity | ||||||

| Maximum Process Operating Temperature | 400 ºC (max 500 ºC) | 600 ºC | 600ºC | ||||||

| Storage Material | Structured Selected Mineral Aggregates | Structured Selected Mineral Aggregates | Structured Selected Mineral Aggregates | ||||||

| Configuration | Monolith | Monolith | Monolith | ||||||

| Dimensions | (5×2.5×6) m | According to configuration | According to configuration | ||||||

| Heat Exchanger | Electric Resistance | Electric Resistance | Electric Resistance | ||||||

Thanks to CADE’s innovative DNA and initiatives, such as EDITOR or TES4Trig, CADE has managed to develop its own solid thermal storage solutions and technologies (solidTES) based on different materials such as solid aggregates or special types of concrete.

Keep yourself updated

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

If you please, contact us and tell us about your project to inform you what we can do for you

We inform you about our engineering solutions