The energy transition towards a more sustainable model is one of the main challenges we currently face. The ambitious decarbonization goals aim to reduce emissions and transform energy supply into a more sustainable model, shifting from a sole reliance on fossil fuels to integrating various renewable energy sources. One of the key tools enabling this energy transition is advanced simulation.

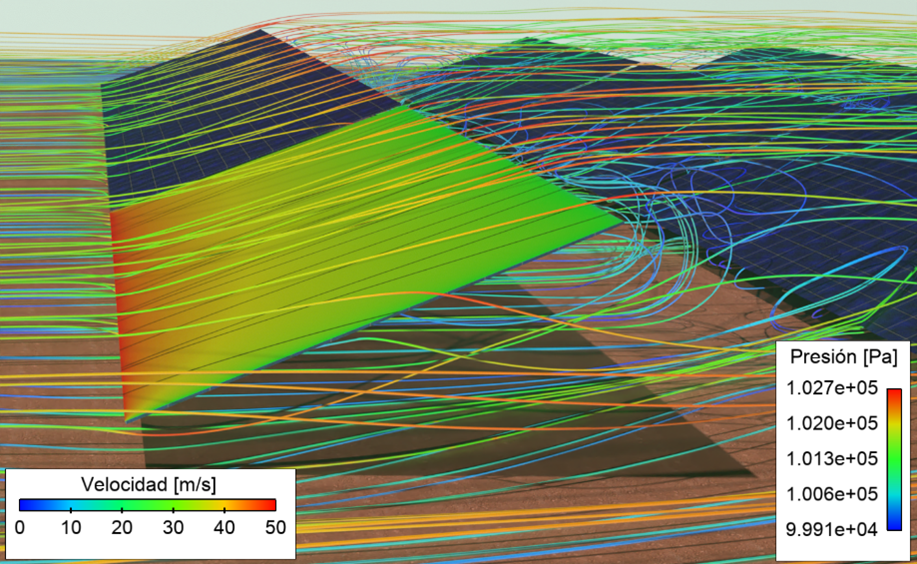

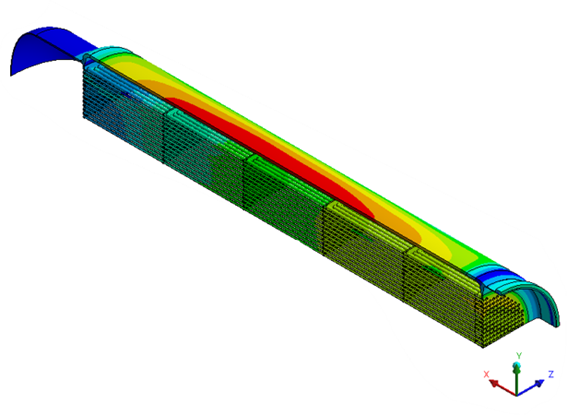

Thanks to both structural and fluid-dynamic simulation, it is now possible to improve the efficiency of solar and wind energy generation processes by developing highly accurate computational models. These models allow for the assessment of not only structural performance but also other key factors that maximize energy generation, such as the location of plants and parks, the orientation of panels and turbines, and fluid-structure interaction.

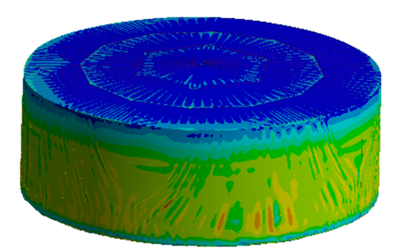

On the other hand, process optimization is already a reality in industrial plants. By studying operational modes and conditions, it is possible to detect inefficiencies in these patterns and predict, through the development of virtual models, the response of critical assets. This is done not only from a process perspective but also from an integrity standpoint, enabling failure anticipation and the implementation of both predictive and prescriptive maintenance strategies.

It is worth highlighting that the use of advanced simulation is facilitating and accelerating the development of new technologies for green hydrogen production, carbon capture, and energy storage. The feasibility and efficiency of these new technologies can be tested, redesigned, and optimized through virtual replicas, without necessarily having to go through real prototypes, which have a much higher economic cost.

A crucial aspect is that finite element simulations make it possible to evaluate the suitability of different materials, allowing for the selection of the most appropriate ones based on their mechanical properties, thereby opening the door to the potential use of new materials.

At CADE, we are aware that the path to decarbonization is complex and that the use of tools such as advanced simulation is a decisive element in accelerating the transition to more sustainable energy sources. For this reason, we offer solutions such as SimulTwin, our digital twin that allows for monitoring equipment behavior, obtaining comprehensive information about current performance, and, most importantly, predicting future behavior and anticipating potential problems.

Considering the lifespan of industrial plants and their costs, the decarbonization strategy involves not only partial replacement or improvement of existing facilities but also the study of possible service changes or equipment rerating to increase plant efficiency. Through the execution of Fitness for Service studies, in which CADE has extensive experience at all levels proposed by the API 579 / ASME FFS-1 code—including the most complex levels that require the use of advanced simulation—it is possible to conduct integrity studies, performance evaluations, and determine the remaining life of equipment and assets.

We can confidently say that advanced simulation is enabling a faster and more efficient energy transition. That is why at CADE, we advocate for a shift in approach when tackling projects that require the use of advanced simulation. We have proprietary supercomputing resources and have developed our own automation tools, allowing us to perform calculations that were unimaginable just a few years ago.