Predictive maintenance is a key strategy in industrial asset management, both in refineries and solar thermal plants. Unlike preventive maintenance, which is performed at fixed intervals, condition-based maintenance is carried out only when data indicates it is necessary. This optimizes resource use and reduces downtime.

Predictive maintenance relies on monitoring the condition of equipment, allowing for early failure detection and better maintenance operations management, reducing maintenance costs, extending asset lifespan, and ensuring safer and more cost-effective operations.

WHAT IS PREDICTIVE MAINTENANCE?

Predictive maintenance is based on monitoring and data collection from equipment and pipelines. Thus, Royal Decree 809/2021, dated September 21, which approves the Regulation on Pressure Equipment and its complementary technical instructions, establishes that corrosion affecting equipment and pipelines must be controlled, requiring sufficient technical information for each asset to understand the existing corrosion margins. Inspection controls must be conducted well in advance before these corrosion margins are exhausted. Additionally, the decree mandates monitoring the reduction in thickness over time using appropriate software programs.

The equipment owner is responsible for ensuring that all inspections and maintenance activities are performed as stipulated in the decree.

OBJECTIVE, METHODOLOGY, AND ANALYSIS

The primary objective of predictive maintenance is to guarantee the structural integrity of energy plant assets, maximize their availability, extend their lifespan, and reduce maintenance costs.

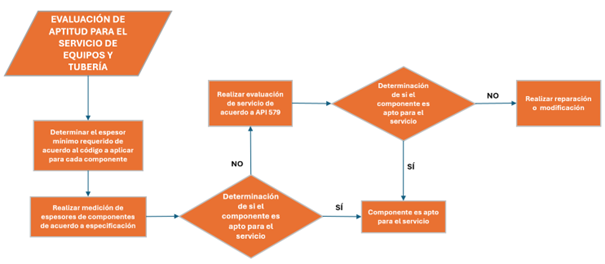

To achieve this, a methodology is followed to prevent failures and ensure the integrity of equipment and installations. Predictive maintenance methodology for equipment and pipelines in energy plants is based on the following steps:

- Monitoring. Continuous monitoring, using sensors and advanced technologies, allows real-time data collection on the condition of equipment and pipelines. Corrosion is the primary degradation mechanism for equipment and pipelines, so monitoring focuses on obtaining thickness measurements at various points of these assets. Thickness measurement is crucial for assessing the integrity of pressure equipment and pipelines.

- Data Analysis. The data obtained in the previous phase, mainly thickness values, is compared with the theoretical minimum thickness values calculated for different operating conditions of these assets. Data analysis is performed using software tools that enable corrosion progression tracking and appropriate planning of inspections and corrective actions.

- Information Management. Information management is essential for predictive maintenance. Data must be stored, processed, and accessible to maintenance personnel. This facilitates informed decision-making and intervention planning.

- FFS Evaluation. If the measured thickness values are below the theoretical values or if failures or defects are detected during asset inspections, an integrity evaluation for fitness-for-service under current conditions (Fitness-For-Service evaluation) will be performed following the rules and methodology established in API-579.

BENEFITS OF PREDICTIVE MAINTENANCE

Implementing a predictive maintenance program offers numerous benefits:

- Cost Reduction: Minimizes maintenance costs by preventing unnecessary repairs and reducing downtime.

- Improved Safety: Detects issues before they become catastrophic failures, enhancing operational safety.

- Resource Optimization: Enables better planning and utilization of maintenance resources.

- Regulatory Compliance: Predictive maintenance helps comply with regulations such as Royal Decree 809/2021, which approves the Regulation on Pressure Equipment and its complementary technical instructions.

EXPERIENCE

At CADE, we have over 15 years of experience in the design and validation of equipment and pipelines, having successfully implemented predictive maintenance in petrochemical industries. We help our clients address major detected failures and schedule appropriate predictive maintenance using information management systems. Our extensive experience in fitness-for-service (FFS), as well as repairs and major repairs, ensures a comprehensive and effective approach to predictive maintenance management.