On January 2, the new Pressure Equipment Regulation (RD 809/2021) came into force. By means of this norm, part of the regulatory vacuum that existed regarding an important sector for the generation of renewable energy in Spain such as is the CSP sector.

The first and most important novelty is that the new regulation includes this type of facility in the Technical Instruction ITC-EP-2 “Power generating plants”, regardless of the energy they can generate. In the previous regulation, this ITC was applicable only to generation plants of more than 50 MW.

Being included in the ITC-EP-2, important regulatory changes apply to these plants in the following aspects:

Categorization:

According to article 3 of the ITC-EP-2, the equipment of the plant is classified as:

- Normal equipment:

- Boilers (main and auxiliary)

- Heat exchangers (superheaters, reheaters, economizers)

- Accumulators, boilers, separators and other containers in general

- Pipes, and safety and pressure accessories

- Special equipment:

- Apparatus filled with resins or filtering materials, or with a fragile or hygroscopic interior coating, such as neoprene, ebonite or vitrified, etc.

Safety regulations:

Article 4 of this ITC indicates the safety requirements regarding:

- Boiler room: The boilers of the plants included in this ITC do not need to be located in rooms with protective walls that limit them. This requirement was already fulfilled since the equipment classified as boilers of these plants (equipment of the steam generation system and auxiliary boilers) were installed as indicated in the ITC-EP-1 “Boilers”

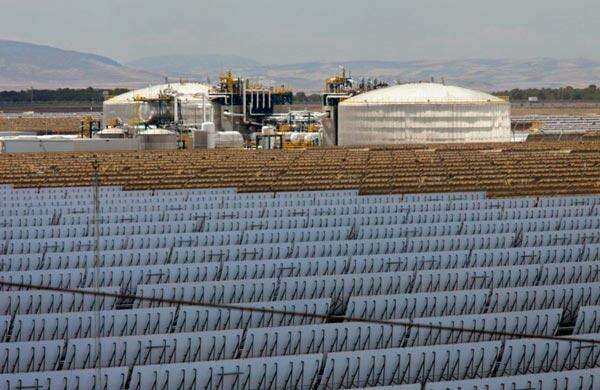

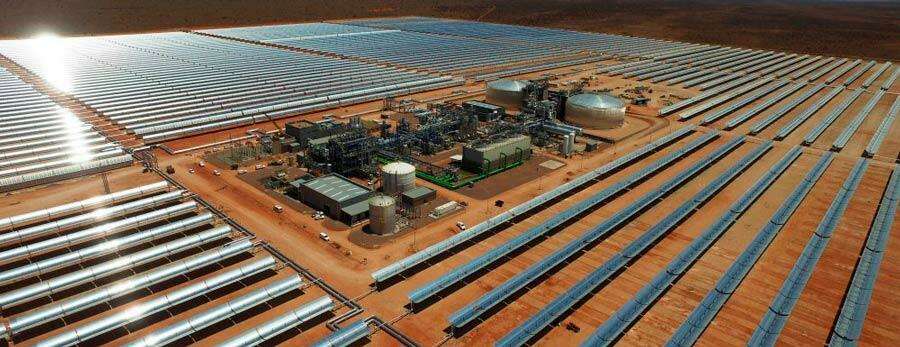

- Safety distance: The pressure equipment of these plants must maintain minimum safety distances from the property line. In most cases, a 35-meter distance would be applied from the projection of the outdoor pressure equipment to the point closest to the property boundary. This requirement is met by almost all existing plant designs as the equipment is located on a power island surrounded by the solar field.

- Service maximum pressure: If the service maximum pressure (SMP) is lower by more than 10% of the maximum allowable pressure (PS), it will be necessary to present a certificate issued by the manufacturer or by an authorized control body, in which The adequacy of the equipment to the pressure must be recorded, especially with regard to the steam outlet velocities and the discharge capacity of the safety valves. This design requirement was already met by the equipment classified as boilers at these plants (steam generation system equipment and auxiliary boilers), but it is now extended to the rest of the plants’ pressurized equipment.

Periodics inspections:

- Periodicity:

- Level A: The periodicity of the Level A inspection is governed as indicated in annex III of the regulation.

- Level B and C: In this case, as these plants are now within the ITC-EP-2, the annual periods may be considered in equivalent hours of operation, according to the definition of section 5 of article 2, point b) of the ITC , at a rate of 8,760 hours/year and provided that the equivalent hours of operation are achieved in a period not exceeding six years for level B or twelve years for level C.

In the annex to the ITC-EP-2 there is a detailed description of the inspection requirements and tests to be carried out on the equipment.

- Repairs: The news in this aspect is the indication made by article 8 of the ITC to identify the equipment according to the scope of the repairs to be carried out. A repair will be considered a “major repair” when it reaches the following levels:

- Boilers (replacement of pressure casing or tubes if >2% heating surface in different parts, boilers or collectors regardless of welding, and/or repairs with heat treatment). Exception cuts in tubes for inspection or in superheater (RX or equivalent 100% welds)

- Heat exchangers (shell operations in >10% weld/chamber total length, heat treatment, replacement 10% tubes or more)

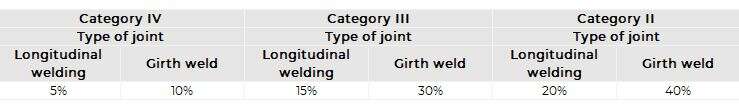

- Other equipment (cat I, cat IV are not considered in tubes >DN80, cat II and III do not consider tubes or coatings, heat treatment, replacement of 15% tubes, or welding lengths that exceed the following table:

- Piping systems:

- PWHT requirement or e>12mm at both ends

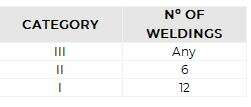

- No. of welds between tubes according to category

As the repair has the scope of “major repair”, it will be necessary to carry out a Technical File by the repair company, with a series of requirements indicated in point 3 of article 8 of the ITC-EP-2.

- Test pressure values after commissioning: Article 10 of the ITC indicates how to calculate the periodic test pressure in case it is not indicated by the equipment manufacturer:

- Design or manufacturer code value

- If the value is not available:

- Pressure equipment except boilers: PT= 1.1xPS

- Boilers: PT=1,1xPms

With the old regulation, the value of this test was the same as that of the initial test pressure, since these facilities were not included in the ITC-EP-2.

- Other controls: Article 13 of the ITC refers to the need to carry out other controls that were not necessary before, as these facilities are not included in the ITC. These controls are:

- Corrosion control:

- Margins of corrosion in equipment and pipes. Applicable to all parts of the systems (equipment and pipes)

- Predictive analysis. Program or tool for corrosion control

- Corrosion under insulation

- Erosion control

- Special controls:

- Specific studies to identify risks that condition the integrity of equipment (evolution of materials depending on operating conditions: structural changes, creep at high temperatures or fatigue, etc.)erm

CADE has extensive experience in the Solar Thermal sector, as well as in the refining and petrochemical sector, providing consultancy and engineering services to properties and O&M companies, and providing technical support for the performance and planning of tests, trials and controls for those who have The pressure equipment of the plants must be subject to compliance with the current regulatory framework.

Further information

For any query or request for additional information about our services and technologies, please complete the following form: