Fiber Reinforced Plastic (FRP/GRP) piping is widely used in industries such as oil & gas, water, and chemicals due to its corrosion resistance and reduced weight. However, its design and installation require precise stress analysis to ensure the structural and operational integrity of the system. The ISO 14692 standard provides key guidelines for the design, manufacturing, installation, and maintenance of these pipes, ensuring their performance throughout their service life.

Safety-Defining Standards: A Regulatory Approach

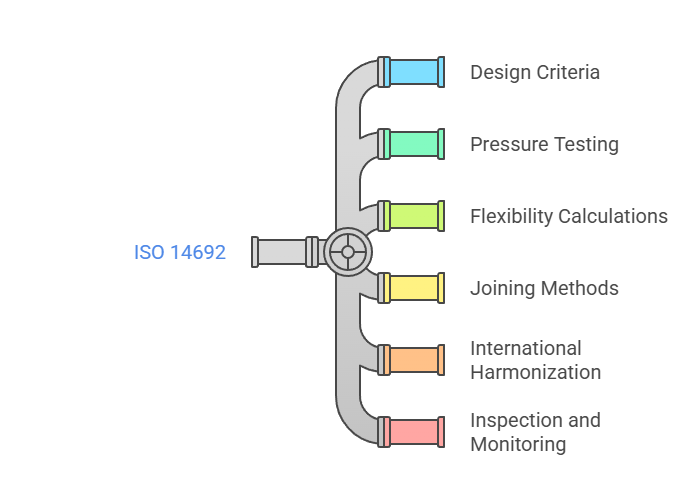

ISO 14692, along with complementary standards such as ASME B31.3 for process piping, establishes design criteria for FRP/GRP piping, taking into account mechanical, thermal, and hydraulic loads. It defines parameters for pressure testing, flexibility calculations, and joining methods, ensuring the safety and reliability of installations. Furthermore, this standard harmonizes international criteria, enabling the standardization of materials and procedures. It also sets requirements for inspection and monitoring of the pipes, ensuring compliance with quality and safety standards across various industrial applications. At CADE, we have expertise in the design and stress analysis of GRP/FRP piping systems, ensuring compliance with standards and optimization of preventive maintenance.

From Theory to Reality: An Applied Approach

In practice, designing FRP/GRP systems according to ISO 14692 allows for optimized installation in aggressive environments. Its application in the oil industry has significantly reduced maintenance costs by minimizing corrosion. Additionally, compliance with standards ensures safe and efficient operations, extending the service life of the infrastructure.

For instance, in offshore platforms—where exposure to saltwater and chemicals is high—FRP/GRP pipes have demonstrated greater durability compared to metallic alternatives. Their installation requires meticulous planning, including the use of proper supports and specific joining methods to avoid stress concentrations. Likewise, continuous monitoring and scheduled inspections, as required by ISO 14692, help detect early potential failures and prevent accidents. CADE has participated in numerous Oil & Gas projects, providing expertise in pipe design and stress analysis, enabling us to implement effective solutions that align with regulatory demands.

Stress analysis under this standard is essential to ensure the structural and operational integrity of FRP/GRP piping, providing safe and cost-effective solutions across multiple industries. CADE’s specialization in applied engineering and its mastery of advanced simulation tools make us a key reference in the design and optimization of piping systems under international standards.