Application Of Api 653 Code To Approach Modifications On Existing Atmospheric Storage Tanks

Table of Contents

API-653 Scope

API 653 “Tank inspection, repair, alteration, and reconstruction” standard covers steel storage tanks built according to API 650 code and its predecessor API 12C. It provides minimum requirements for maintaining the integrity of such tanks after they have placed in service and addresses inspection, repair, alteration, relocation, and reconstruction.

API-653 Requirements in power and process plants.

It is known the high cost and the complexity of manufacturing large storage tanks manufacturing (with a diameter larger than 200 ft). Storage tanks in power and process plants, after years in operation, and due to the continuous modification of operating conditions, must be replaced or modified to comply with new design conditions and/or integrity requirements.

The main question arises: Is it necessary to completely replace such tanks due to the new conditions and requirements?

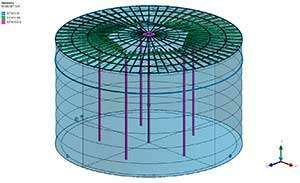

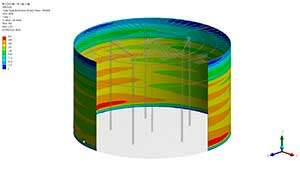

API-653 can be applied for validating and repairing these atmospheric storage tanks by means of evaluation and calculation of the tank according to the new design conditions. After this evaluation, design modifications can be defined as well as repair of damaged or non-compliance parts that result in not valid for new design conditions according to API-653 code. This approach uses to be a more affordable and convenient solution than replace or great repairs.

CADE'S experience with API-650 AND API-653 CODES

CADE counts on more than 15 years of experience around design, calculation, and integrity evaluation of storage tanks according to API-650, API-653, or API-579/ASMEFFS-1 codes. The company delivers first-class engineering and consulting services to Plant Owners, EPC contractors or Manufacturing companies within Oil&Power industries, counting on more than 1500 references worldwide.

Conclusion

CADE engineering is recognized as a top-class engineering and consulting firm due to its holistic and multidisciplinary approach in design, integrity, and performance evaluation of critical assets. CADE’s scope of works includes storage tanks, heat exchangers, process columns, reactors, or pressure vessels, among other equipment. CADE’s team is made up of process, mechanical and structural engineers able to conduct both (design by formula) engineering design and calculation capabilities as well as complex CFD analysis /FEM simulation to evaluate complex physics and design requirements.