Thermal stratification in cryogenic LNG lines, also known as the banana effect, occurs when there is a significant thermal difference between the bottom and top of a pipe. In the day-to-day running of a terminal, the temperature in the lines is relatively uniform, so the associated thermal stresses will not compromise the structural integrity of the pipes. However, it is in unusual operations such as initial cooling during start-up when there are thermal gradients whose effect must be carefully evaluated. Many thermal stratification phenomena cause unexpected damage, both in the pipe itself and in its supports, their effect going unnoticed until these damages are finally discovered.

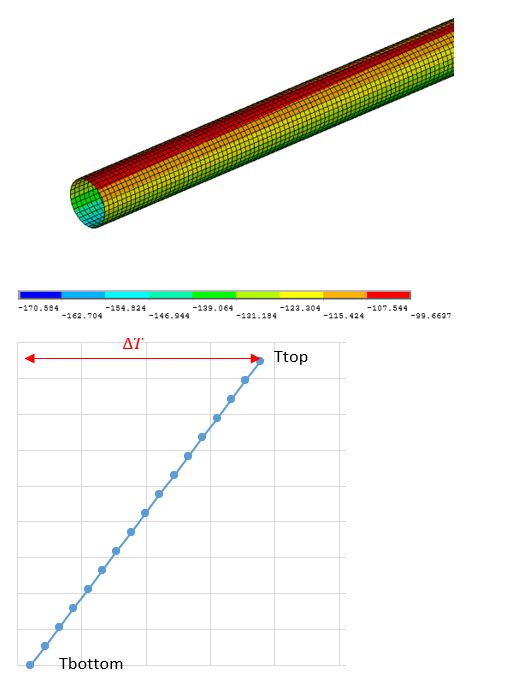

When pipe cooling is not uniform, flow channels are produced at different temperatures; The image represents the temperature distribution for a section of pipe with a thermal gradient of approximately 70ºC between the lower and upper faces. The temperature not only varies circumferentially in the pipe section itself but also longitudinally, simulating a start-up procedure in which sudden cooling of the line was detected.

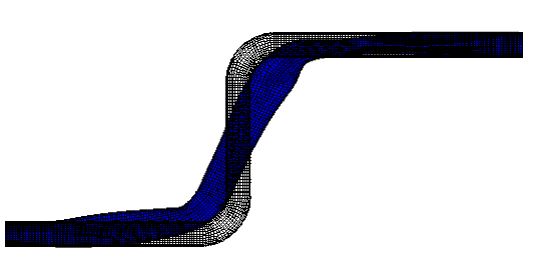

This high thermal gradient produces deformations that induce the curvature of the pipe, since the expansion of the upper part of the pipe is considerably greater than that of the lower part, generating tensions in the line that will lead to the appearance of cracks and permanent plastic deformations. that should be evaluated to anticipate possible failures.

Comparing the tension state of the line analyzing only the effect of loads of mechanical origin with respect to the effect of mechanical and thermal loads due to cooling, the existence of significant effects associated with the phenomenon of thermal stratification is clearly observed, so it will be necessary to carry carry out a more detailed analysis to confirm if this stress state compromises the integrity of the analyzed pipe.

The definition of a correct cooling procedure is essential to ensure the integrity of the pipe during the useful life of the plant since high thermal gradients can generate unexpected failures that can compromise the operation of the plant. In the case of detecting severe cooling during start-up or any other failure in the cooling procedure, it is recommended to carry out a detailed finite element study to evaluate the real tension state of the line, as well as the identification of the regions susceptible to failure being recommended in these areas to carry out destructive tests in addition to those indicated by the code to detect the existence of possible cracks and permanent deformations.

Thanks to the extensive experience in Fitness for Service analysis, CADE has the potential and tools necessary to evaluate the effect of these behaviors on the integrity of equipment or piping lines, both from the design phase and in operation, identifying those regions susceptible of cracking and permanent deformation, and analyzing the remaining life of this equipment. In this way, it is possible to safely extend the life of damaged equipment or line.

Further information:

For any question or further information request about our services and technologies, please complete the following form: