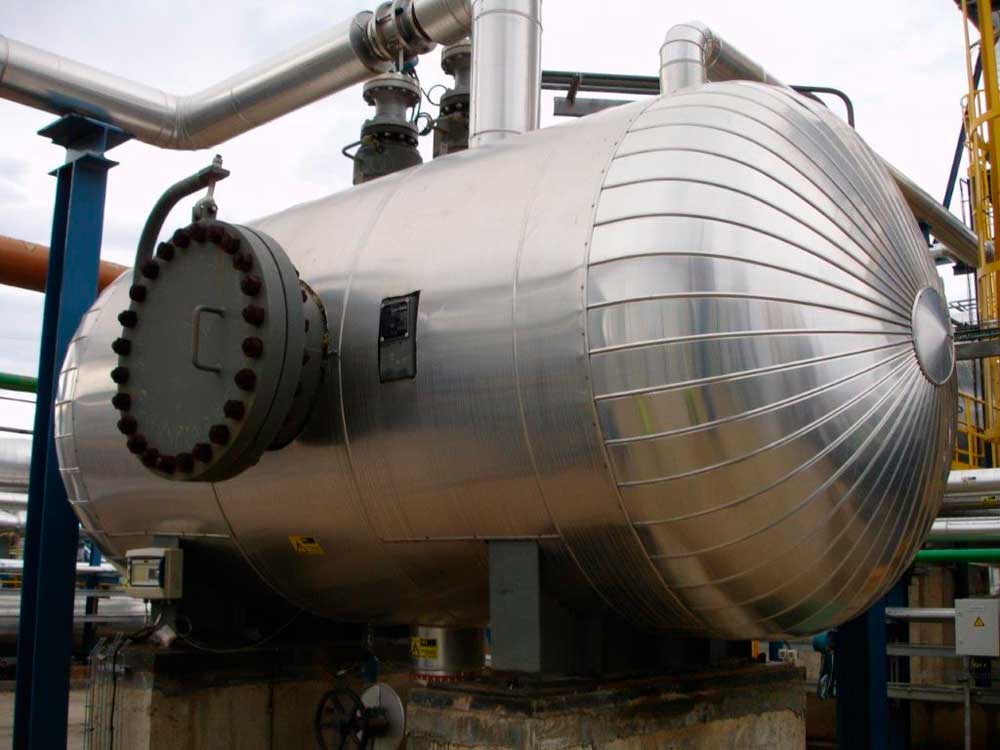

Most of concentrated solar plants installed in Spain are currently immersed on “suffering” level C inspections on their equipment and pressure elements.

Introduction / definitions

The need to perform regular inspections on pressure equipment arises from the compliance with the Spanish pressure equipment regulation (RD2060 / 2008) and its complementary technical instructions (ITC’s by its acronym in Spanish). For this, it is necessary to clearly know the definition of pressure equipment:

“Containers, ducts, safety elements and pressure elements. It will be considered part of pressure equipment, elements fixed to parts subjected to pressure such as flanges, nozzles, couplings, brackets, supports, lifting lugs, etc.” (RD 769/1999 repealed).

In order to identify the type of equipment which is subject to periodic inspections, it is necessary to know the pressure equipment category, according to the fluid type contained, maximum allowable pressure, its volume or diameter, etc.

The following regulations may apply to pressure equipment in order to define its classification:

- D. 769/1999

- Regulation of pressure equipment and ITCs (D769/1999 is repealed, although it is referred for the definition of certain terms and the classification of the pressure equipment type.)

- D. 2060/2008

- Regulation of pressure equipment and ITC’s in force.

- DIRECTIVA 2014/68/UE

- Harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment.

- D. 709/2015

- Safety requirements for making available on the market of pressure equipment. Directive Transposition 2014/68 / EU

- Reglamento 1272/2008

- Classification, labeling and packaging of substances and mixtures.

According to these regulations, pressure equipment is classified into categories according to the following criteria:

- Type of fluid (hazardous (type 1) or not (type 2))

- Maximum allowable pressure

- Diameter (duct) or volume (container)

Based on these criteria and its applicable regulation, pressure equipment is categorized into:

- Category I

- Category II

- Category III

- Category IV

- SEP or ART 4.3

Based on pressure equipment category, it is defined the type and frequency of the periodic inspections:

- LEVEL A: Inspection in service. Visual and documentary inspection.

- LEVEL B: Inspection out of service. Level A + Thicknesses, safety tared, and NDTs required.

- LEVEL C: Inspection out of service with pressure test. Level B + Pressure test.

Periodicity for level C inspections is 6 or 12 years, depending on the equipment category and its service since start up date.

When legalizing modifications made in plants due to the execution of level C inspections in Spain, there are some differences between the different Spanish autonomous regions, despite sharing the same regulatory framework. These differences come from the fact that some of these regions have developed their own procedures or guidelines for the application of the regulation, in order to clarify or define how the documentation should be submitted to the corresponding Regional Administration.

Problem identification

In thermosolar plants, there are various pressure equipment categories that must undergo periodic regulatory inspections. Both level A and level B inspections do not usually imply any type of problem when executing. However, with level-C inspections, certain issues may arise due to the approach taken in the design of the plants. The design approach of the plants is based on the following concepts:

- Minimization and / or avoidance of leaks, by means of welded joints

- Plant Availability

Problem solution

Once the problem has been identified, it is time to identify the available solutions and alternatives in order to carry out the required hydraulic test. In this regard, it is necessary to sectorize those pieces of pressure equipment to be tested in a way that allows grouping items according to the following criteria:

- Type of fluid

- Test pressure

- Closeness/ interconnections between pieces of equipment

- Minimization of number of circuits

It is hardly possible to meet all the criteria one by one. For this reason, in order to group different circuits with slightly different test pressures, it is sometimes necessary to request substituting tests to make a test in particular conditions, different from the ones that should be taken according to design input. Such substituting tests implies:

- Test pressure decrease or increase in specific pieces of pressure equipment which are part of a defined test circuit:

- Test pressure decreases when there is a fusible element whose pressure design is below test pressure conditions. In this case, test pressure is limited to the pressure that the fusible element can hold.

- Test pressure increases when, in a specific circuit, there is a piece of pressure equipment whose design pressure is below the rest of equipment’s. In such case, the item with lower design pressure may be able to hold higher test pressures with guarantee of integrity during the test.

- Issuance of the substituting tests report (or particular conditions test report) to justify the adoption of exceptional measures related to the hydraulic test performance: static test with decreasing pressure justification, dynamic test with operation pressure justification, grouping circuits or pieces of equipment, etc., as well as additional inspection tests to complement the regulatory inspection (END’s, visual inspection, etc.). Approval of this measures by notified body shall be mandatory before submitting all required documents to the corresponding regional administration in order to obtain the final approval of such substituting tests.

Identification and definition of plant upgrades

As a common consequence of the CADE’s services focused on complying with regulatory inspections, additional and recurrent problems related to the operation and maintenance of plants have been often identified:

- Flanged joints: it has been identified that not all these elements are bolted with the recommended tightening torque. CADE develops tightening procedures of bolted joints according to the ASME PCC guidelines, both for continuous (refinery plants) and cyclic (CSP plants) operation.

- Typology of valves: there have been identified incompatibilities between materials, the use of not suitable valves for its actual service and/or the application of not optimal solutions to ensure the isolation of circuits during its operation and testing.

CADE provides support for plant permitting and accomplishment of regulatory inspections in different regions. Among the technical services related to such legal topics, CADE offers:

- Basic engineering:

- Test circuits selection n and setting up

- Analysis of test pressures of circuits

- Analysis of fusible elements for testing (necessity of substituting tests)

- Elaboration of test P&IDs

- Process and / or operation upgrades

- Detailed engineering:

- Isometrics modification incorporating new elements

- MTOs

- Execution Supervision of modifications and hydraulic tests

- Legalization:

- Issuance of execution reports: modification works required to conduct hydraulic test

- Issuance of substituting tests report

- Coordination with notified body for the execution of hydraulic tests and additional inspections

- Project Addendum for pressure equipment legalization

- Technical dossiers of CE marking in case of new equipment (pipes or vessels) or rerating due to modifications or design conditions