Integrating with existing conventional system

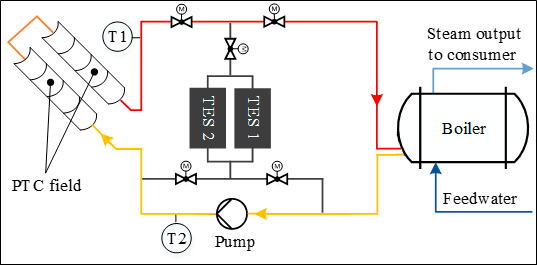

KEAN uses a fossil-fired boiler to produce saturated steam (188°C, 11 barg) for different industrial processes to produce their juices and soft-drinks. The solar power system designed in EDITOR is integrated with the existing conventional system without performing any modification in the existing boiler system.

Emissions reduction

EDITOR produces more than 5 % of the total KEAN’s saturated steam demand covering a substantial portion of the factory normal consumption and supporting the fossil-fired boiler during the de-juicing periods, which leads to a reduced consumption of fossil-fuel and reduction of the CO2 emissions.

EDITOR's main equipment

This plant’s main equipment, which occupies a total ground area of 1250 m2, is listed below:

- 125 kWth two-row PTC field with a total dimension of 50m x 12m

- Two 20 ft standard containers for the 600 kWhr concrete thermal energy storage

- One 20 ft standard container for the kettle-type boiler, thermal oil pump and control system

Due to the installation of the solid-TES energy storage system, system pre-heating activities are optimized and solar energy produced steam is delivered during the night and during the cloudy days. Weekends and non-operational days are utilized to fill the thermal storage in order to maximize the solar production.

EDITOR's Workshop 2019

An at-site Workshop day about EDITOR and SolidTES will take place in Limassol (Cyprus) on June 18th, 2019.

If you are interested to attend, please contact vruiz@cadesoluciones.com or complete the following contact form to request further information.

SolidTES challenge in EDITOR

Solid Thermal Storage System

SolidTES is a Thermal Energy Storage system based on solid-state blocks modularly added to achieve demanded thermal energy capacity ranging from 150 and up to 500 ⁰C.

Solid blocks are traversed by steel tubes exchanging heat with internal heat transfer fluid (HTF), thermal oils, molten salts, air, pressurized water or steam coming from both conventional or renewable heating sources (gas boilers, concentrated solar power, etc.).

Due to its extreme thermal capacity, it is possible to provide a very compact and cost effective system (LCOE ~ 0.01 €/kW)[1]. SolidTES is a secure, easy, stable, firm, strong, massive, sound and reliable thermal storage solid solution.

SolidTES thermal energy storage system is charged by sensible heat using HTF* up to the required temperature and discharged during process heat demands by heating colder HTF. Available HTF medias range from water, steam, air up to thermal oils and molten salts.

SolidTES storage system optimizes thermal process heat plant operation by better utilization of solar energy:

- Modular and scalable system, up to several MWth, allowing for 24h continuous solar thermal energy supply.

- Solid-state storage technology using specially developed and innovative materials with superior thermal performance. For EDITOR project, HEATEK® material developed and supplied by Arraela was used, due to its excellent fit to the project requirements.

- Operation over a wide storage temperature range, up to 500°C or even higher by special design, by different materials formulation and components specification.

- High efficiency of storage (94%).

- High operational flexibility, robustness and simple O&M.

- Durable and safe technology.

- Efficient manufacturing process and logistics (precast or site casting supply).

EDITOR's objective and team

- Protarget AG (Cologne, Germany)

- CADE Soluciones de Ingeniería, S.L. (Albacete, Spain)

- Cyprus University of Technology (Limassol, Cyprus)

- German Aerospace Center (Cologne, Germany)

- Solar-Institut Jülich of the Aachen University of Applied Sciences (Jülich, Germany)

[1] LCOE – Leveled cost of energy for a typical 8 hours/day, 200 days/year and 20 years operation for a typical 750 kW installation