News

CADE launches CADE COBOTS. Collaborative robotics solutions.

The aim of this new line of business, named CADE COBOTS, is to develop, supply and integrate complete “turnkey” solutions for the automation and optimization

CADE to participate as speaker in the CSP FOCUS MENA 2018, next June 27-28 in Marrakech Marocco

In Session 5: Frontier Technologies and Research Results, CADE will present progress and results of the most promising R+D projects in which the company is

CADE exhibitor at PRC Berlin 2018 (Petrochemical and Refining Congress)

Thanks to all delegates, exhibitors and speakers of the Petrochemical and Refining Congress in Berlin (PRC Europe 2018) for such high quality attendance and papers.

MSLOOP PROJECT: THE NEW GENERATION OF CSP PLANTS

MSLOOP aims to validate a technology consisting of developing a cost effective solar field for CSP Parabolic Trough Power Plants using optimized ternary molten salts

Looking forward. Advanced Mechanical Solutions

CADE initiated last October 25 the 5th edition of its course about ANSYS WORKBENCH in Albacete School of Industrial Engineering, frameworked within the collaboration that CADE

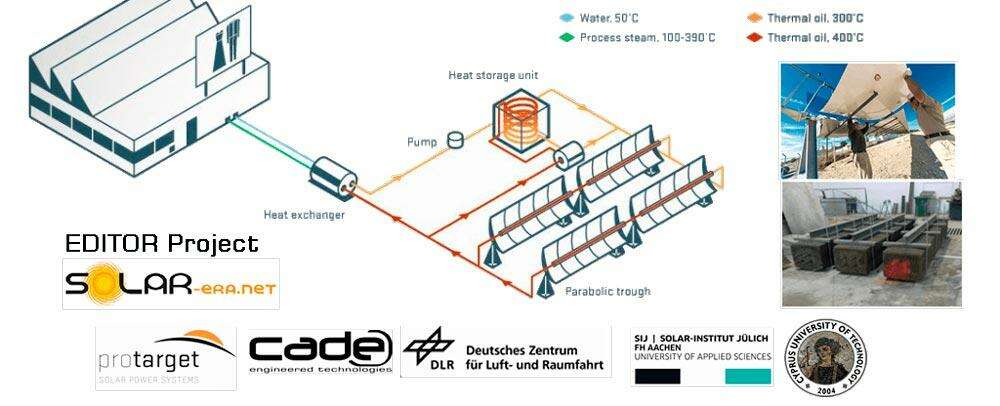

EDITOR Project. 24h Continuous thermal power supply based on CSP and concrete thermal energy storage

The system shall consist of a mid-sized parabolic trough collector loop combined with a concrete thermal energy storage, and it is experimentally designed for industrial

CADE: lecturer at Seminar of Energy – CIEMAT

CADE will be present as a lecturer on the 2nd Edition of the Energy Seminar that will be held next February 23rd 2016 at CIEMAT

WORKSHOP 2015: THANKS FOR YOUR ATTENDANCE

CADE would like to thank those who attended the workshop celebrated last Thursday, 26th of November, at the Via Castellana Hotel, in Madrid, for their

2nd WORKSHOP: ADVANCED ENGINEERING METHODS FOR EVALUATION OF CRITICAL EQUIPMENT AND PIPING SYSTEMS

Thursday, November 26th, 2015, Hotel Vía Castellana (Madrid) Overview The seminar shall be focused on the problematic, methodologies, novelties, and benefits associated to the evaluation