Collaborative Palletizing: Flexible and Safe Automation for End-of-Line Operations

Una solución de automatización adaptable, segura y eficiente para optimizar el final de línea industrial

📍Spain

Project

Description

The project focused on the development and integration of a collaborative palletizing system designed to automate the end-of-line process in a packaging facility. The main objective was to replace a repetitive manual task, handling and stacking boxes of different sizes and weights, with a flexible, safe, and efficient robotic solution.

The installation had to adapt to multiple product formats, ranging from small 50 ml containers to 500 ml bottles, while maintaining the precision and production rate required by the line. This demanded a versatile and easily reconfigurable system, fully compliant with collaborative safety standards for human-robot interaction.

The solution was delivered as a turnkey system, encompassing mechanical and electrical engineering, robot integration, programming, CE marking, documentation, transportation, commissioning, and operator training. The project was executed through an integrated approach that combined CADE’s expertise in industrial automation and its solid background in collaborative robotics applied to real production environments.

The

Challenge

The main challenge was to automate a process traditionally carried out by manual labor, without relying on large, enclosed robotic cells or physical safety barriers. The system needed to coexist safely with operators, ensuring true human-robot collaboration within a compact footprint.

The variety of box formats, with differences in dimensions, weight, and pallet height, required high design flexibility. The system had to identify and handle each type of packaging without complex reprogramming, maintaining a minimum throughput of 5 to 7 boxes per minute and a final pallet height of around one meter.

Another critical aspect was the variability of packaging materials and palletizing patterns, which demanded an adaptable vacuum gripper system and intelligent control software capable of managing multiple layouts. Additionally, the production environment imposed demanding operating conditions, with continuous cycles, frequent format changes, and the need to minimize downtime.

CADE developed a fully automated collaborative palletizing cell, centered on a 20 kg-payload collaborative robot designed to operate safely alongside human workers.

The system includes two pallet positions with positioning sensors, a stainless-steel supporting frame, an interchangeable vacuum gripper, a touch-screen control station, and fully integrated electrical and pneumatic systems. Its modular design allows easy adaptation to new formats or additional production lines.

The robot is programmed through an intuitive interface and provides safe Collaborative Palletizing operation without fences, using advanced force-limiting and collision-detection technologies. The control architecture includes emergency stops and laser safety scanners compliant with CE standards, ensuring reliable and secure performance in industrial environments.

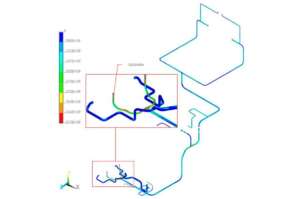

The engineering phase included 3D simulations, maneuver testing, and in-house handling trials to validate box gripping and optimize cycle times before delivery. The commissioning stage included on-site installation and operator training, ensuring a smooth transition toward automation.

Solution

CADE’s

Results

The new Collaborative Palletizing solution eliminated repetitive, ergonomically demanding work, reduced handling time, and significantly improved overall production continuity and efficiency. Automation lowered dependence on manual labor while enhancing safety, reducing repetitive-strain injuries, and improving product consistency and quality at the end of the line.

Thanks to its dual-pallet configuration, the Collaborative Palletizing cell operates continuously: while the robot completes one pallet, the operator replaces the other, keeping workflow uninterrupted and ensuring sustained cycle times even during shift changes.

The system’s flexibility allows rapid format changes without complex programming, ensuring true adaptability and scalability to dynamic production environments and future automation needs.

The outcome is a compact, reliable, and efficient Collaborative Palletizing system that merges cutting-edge technology, operational simplicity, and industrial robustness. This project clearly demonstrates how Collaborative Palletizing automation can transform end-of-line operations by combining productivity, ergonomics, and sustainability in a single, future-ready solution.

Otros Proyectos

Design and Analysis of a Flexible Pipe Connection on Creep Range

Design and Analysis of a Flexible Pipe Connection on Creep Range Objective An equipment manufacturer required CADE to conduct the validation design of a flexible pipe connection, between a reactor

Structural Integrity Assessment During Local PWHT

Structural Integrity Assessment During Local PWHT Post weld heat treatment (PWHT) is a thermal treatment usually performed in steels that have been welded. Its object is to ensure that the welding properties are suitable for its expected operation according to

3D Point Cloud Generation to Modify Existing Systems

3D POINT CLOUD GENERATION TO MODIFY EXISTING SYSTEMS OBJECTIVE In projects for the modification or upgrading of existing industrial facilities, CADE regularly performs 3D laser scans in plants, in order

Piping Stress Analysis and Finite Element Analysis (FEA) For Creep Effect Evaluation

PIPING STRESS ANALYSIS AND FINITE ELEMENT ANALYSIS (FEA) FOR CREEP ASSESSMENT The owner of a steel plant in DURGAPUR (India) requested CADE to assess the remaining life and mechanical integrity