Nowadays, many factors are seriously affecting major oil companies. Market conditions and uncertainties, aging assets, or decarbonization requirements will necessarily impact on their future investment strategies and business models. A transformation of their business paradigm is not only a challenge right now but also an opportunity as well, to continue leading the industry of energy.

CADE is actively collaborating with some of the most recognized oil companies in the world to approach and assess the current condition of existing plants and assets. Based on a significant track record of integrity consultancy projects, CADE is becoming a reference company to come along with plant owners to face complex evaluation and updating projects of aging assets.

Table of Contents

CADE´S APPROACH

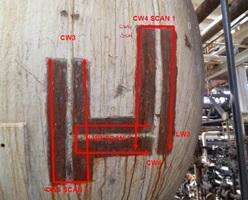

The following approach and methodology are the result of CADE’s experience around asset assessment and integrity consultancy projects for oil refineries and power/ process plants. CADE’s services range from Fitness For Service assessment (Levels 1 to 3), remaining life assessment, up to remediation solutions, monitoring, and repair or replacement of equipment and piping.

STEP 1: SCREENING

This first stage will consist of reviewing the existing documentation, operation data, maintenance and repair history, corrosion margin, among others.

After that, preliminary calculations of minimum thicknesses for current operating design conditions are conducted for comparison with thickness readings or estimated thickness, according to the original design code, as well as, in those cases where performing measurements is not possible.

The aim of this phase is, after a thorough review of the design conditions and operation history data, to identify those items that need to be evaluated through Fitness For Service methodology (FFS)

CADE´s experience in similar integrity works (by asset typology and quantity) proves that an efficient screening before FFS assessment determines the results of the study in terms of time, quality, and cost.

STEP 2: FFS ASSESSMENT

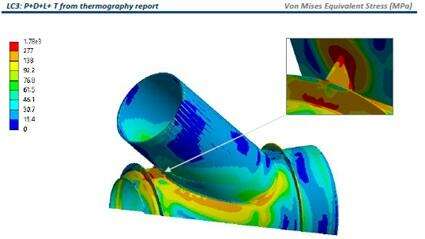

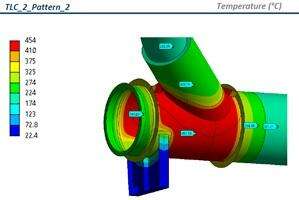

FFS assessment Level 1, 2, and/or 3, according to API 579-1/ ASME FFS-1, shall be conducted by considering those defects found or identified in the inspection plan:

Fig. FFS Assessment Procedures for Various Damage Classes (Source: API 579-1/ASME FFS-1)

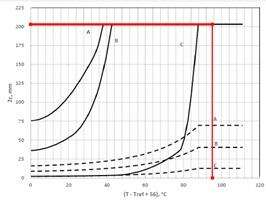

REMAINING LIFE ASSESSMENT

In case of FFS assessment determines equipment or any of its components is suitable for operation, an RLA (Remaining Life Assessment) is conducted to determine and define an appropriate inspection interval, in-service monitoring plan, or remediation measures, depending on the case.

This state aims to provide an adequate safety factor for operation until the next scheduled inspections works are executed. Whether the estimated remaining life is short, or it is not affordable to esteem the future damage progression, CADE should propose an in-service monitoring plan.

When results of previous stages conclude that a component or an item, such as a pressure vessel, atmospheric tank, or pipeline, is not suitable for operation considering its current conditions, a proposal for repair or replacement is issued.

CADE: INTEGRITY ENGINEERING EXPERTS

CADE is an independent leading engineering and consultancy company around technology, equipment, and plants within Oil & Power industries. The company counts on a significant track record on integrity assessment in refineries, power, and process plants worldwide.

Whether global integrity projects covering a whole plant or specific consultancy services focused on specific critical items, CADE provides a full range of services and capabilities to help owners on strategic decisions when assets are about to enter in the final stage of expected lifetime.

CADE’s capabilities include heat transfer, materials, mechanics, welding, thermal and mechanical design, inspection, or manufacturing processes, among others. Such capabilities, together with sound engineering methodologies, cutting-edge finite element simulation software, as well as an in-deep knowledge of applicable standards, are all put together to provide a comprehensive response to the complex challenge that costly and aged asset means.

Further information:

For any question or further information request aboud our services and technologies, please complete the following form: