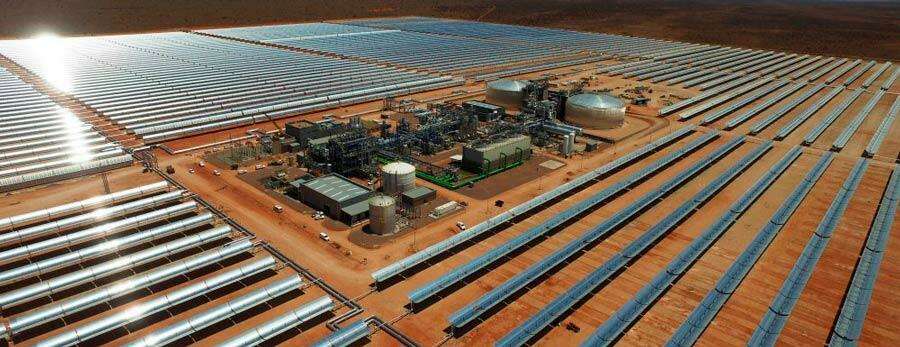

The forefront of the Solar Thermal sector since 2006

Engineering & Consultancy in CSP Plants

Activities and Capabilities in the

CSP Sector

Solar thermal generation technology (Concentrated Solar Power – CSP) is where all of CADE’s capabilities clearly materialize from the beginning of the sector, as a strong and reliable partner throughout the entire project life cycle, ranging from I + D to operating plants.

CADE develops new technology and engineering concepts around improving the efficiency and availability of existing CSP plants, as well as new concepts of solar thermal technology applied to the heat consuming industry.

Owner’s Engineering

FEED Engineering (Front-and-End-Engineering Design), Selection and evaluation of main equipment and systems, Technical-Economic Feasibility Studies (CAPEX-OPEX), Generation EPC Sheets and Specifications,

EPC project execution control.

Permitting / Ready-to-Build

Basic Project

Project Applications and Authorizations

Processing with the Administration

(Municipal/Regional/National)

Basic and detail Engineering

Multidisciplinary engineering for conceptual and detailed development of CSP >50MW plants:

- Solar Field- HTF

- Steam Generation

- TES – Thermal storage system in molten salts

- Power Block

Procurement

Equipment, Package Units, Contractors

Specifications of purchase and technical tabulation of offers

Manufacturing and supply monitoring and monitoring

Workshop inspection and equipment reception

Construction Supervision

Civil, Mechanical Systems, I&C, Electricity

Commissioning

Definition of protocols, manuals and PEM tests

solidTES – Thermal Storage

Concrete and aggregate-based thermal storage technology

R&D

Evaluation of the Dispatchability of a Parabolic Trough Collector System with Concrete Storage – EDITOR

Feed and conceptual engineering

Integration with:

- existing processes (steam, hot water, thermal oil, air, electricity)

- existing energy sources (residual heat, PV, thermal or electrical discharges)

- Basic and detail engineering

- Turnkey Projects

ProcessCSP Industrial Heat

Solution for thermal contribution to the industry based on concentration plot with parabolic cylinder or Fresnel technology and with thermal storage.

Feed Engineering, Conceptual and Technology Assessment

Integration with existing processes (steam, hot water, thermal oil, air, cold systems)

Basic and Detail Engineering

Turnkey Projects

Digital CSP plant

Digitalization portfolio and industry 4.0 focused on solar thermal plants

Improved asset management and O&M under paradigm 4.0, from specific equipment or asset, units or systems, to complete plants

Intelligent 3D plant model:

- LASER 3D SCAN: Point clouds generation and photorealistic plant models for improved management

SMART 3D mockups: 3d model generation including asset data and information and operation and maintenance

Digital twin: real-time critical asset monitoring and analysis for decision-making and prediction:

- Condition-based and predictive maintenance

ANALYSIS-MONITORING of status, integrity, life and failure prevention of critical equipment

Complete DIGITAL TWIN of equipment or systems with sensorization, monitoring, intelligent analysis, simulation and experimentation capability, to improve the performance and efficiency of the equipment or system.

InCycle

Methodology for the analysis and optimization of renewable steam cycles.

Water Quality Analysis vs Industry Standards and Regulations

- Review of the sampling system

Review of the dosing system

Analysis of the current status of computers:- Corrosion (pitting, FAC, low tank, …)

Fouling, performance, by-passes, etc).

Accumulated damage from current operation (fatigue, thermal shocks)

- Corrosion (pitting, FAC, low tank, …)

- Identification of operational improvements to avoid detected deviations (increased service life, improved performance)

Cycle performance analysis

Reduction of leaks (PSVs, drains, purgers)

Plants in

Operation

Currently, more than 25 CSP plants operating around the world count on CADE to evaluate, optimize, and improve the main systems and critical equipment of the plant.

Executed Type

Projects

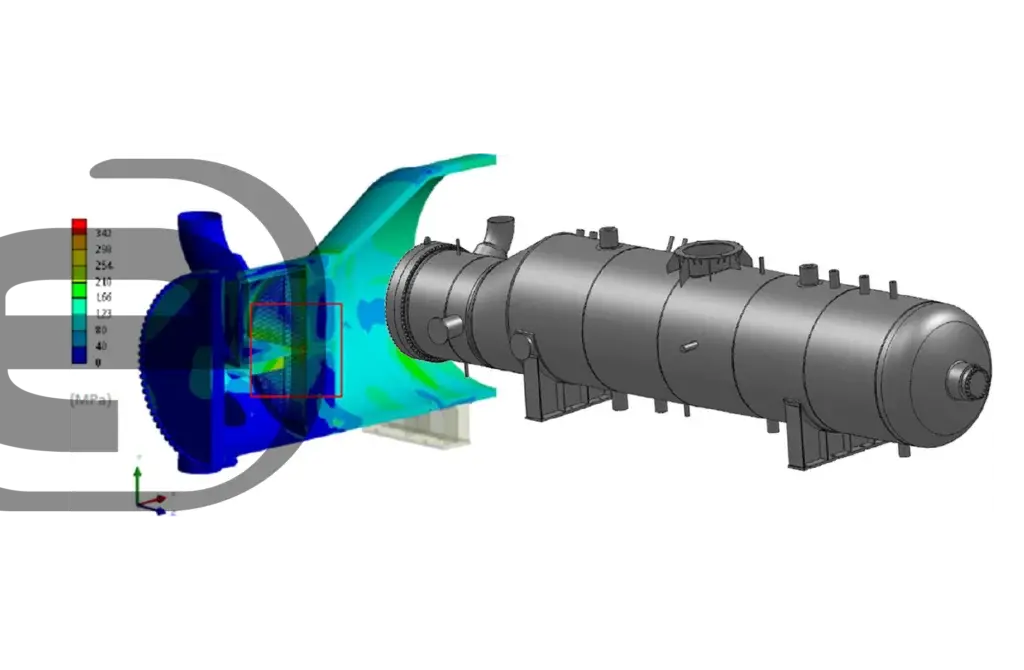

Static Equipment: Steam generation train, salt exchangers for trains, salt storage tanks

Evaluation of nominal and actual partial loads vs. design

Thermal shock analysis

Fatigue assessment

Vibration analysis

Dynamic Equipment: Main pumps, feedwater pumps, molten salt pumps

Analysis of operating points vs. design curves (Q min, Q max, BEP)

Vibration analysis

O&M analysis vs. operation

Main Results:

Evaluation of accumulated damage and determination of remaining life

Identification of operational limits (thermal shocks, heating ramps, flow rates)

Identification of operational improvements, maintenance improvements, and mechanical improvements

Optimization of pump consumption

Identification of thermal losses

General maintenance status of plant or plant systems

Thermal and Hydraulic Simulation of HTF/Salt Heat Exchangers

Simulation of heat exchangers according to manufacturer documentation

Analysis of operational data based on DCS

Main Results:

Optimization of energy supply and charge/discharge curve: Energy exchanged curves as a function of operating flow rates

Influence and identification of the Q HTF / Q SALTS ratio vs. tube temperature: Integration of DCS safety measures to prevent exceeding manufacturer limits

Operational limits due to vibrations

Simulation of failure events: System operation with the remaining exchangers

Key Outcomes:

Power curve as a function of the number of available exchangers

Design of a bypass system for operation in case of failure. Basic and detailed engineering

Thermal and hydraulic simulation of the Steam Generation train

- Simulation of heat exchangers according to manufacturer’s documentation

- Operating data analysis according to DCS

Main results:

- Equipment actual response Vs. Project

- Performance analysis and power loss (heat)

- Accelerated fouling identification: low performance, DeltaP increase

- Identification of steaming and vaporization phenomena in

- Preheater: fouling, erosion.

- Identification of mechanical risks due to vibrations

- Proposed operational improvements

- Proposal and definition of DDs if required: boronscopy, thickness measurement, analysis of samples and residues (during operation, during stoppage)

- Analysis of the performance of the other equipment available under the hypothesis of failure of one of the train equipment

- Analysis of the potential flow increase in all other available equipment for production reduction compensation for equipment that fails

- By-pass system design (basic and detail engineering)

Root cause analysis to determine the origin of cracks in the roofs of salt tanks and definition of proposals for improvement and solution of the problem.

- Tank inspection (visual inspection, thickness measurement, identification of areas with internal corrosion using MRUT methodology, temperature control and measurement in hot areas of the tank)

- Operating data analysis according to DCS

- Thermal-structural simulation under standard operating conditions

- Assessment against fatigue and thermal shocks

- Tank simulation during the warm-up process

- Assessment of foundation settlements in tank structural behavior

- Vibration assessment in piping systems

- Corrosion assessment due to air tank contamination.

Stress Corrosion - Cracking Assessment (SCC).

- Chemical analysis of salts

Main results:

- Identification of mechanical risk associated with vibrations in connections

- Identification of mechanical risk in piping due to the effect of settlements

- Identification of mechanical risk due to the preheating process

- Identification of mechanical hazard due to vibrations

- Water Quality: Operating Condition Review (DCS and Plant Analytics) Vs. Recommended Values

- Effect/Impact of water quality on core equipment

- Exchangers: corrosion, depositions, loss of performance

- Steam turbine: Fouling (Na, Si, Metal oxides) and loss of performance

- Mechanical carryover analysis in Steam Generator (SuperHeater fouling and Steam Turbine)

- Review of the dosing system.

- System review and sampling procedures.

- Thermal analysis of exchangers: by-pass identification, fouling, steaming.

- Mechanical analysis of TGV exchangers (accumulated damage per operation, operational limits)

- Definition of commissioning and stop procedures for the reduction of steaming, corrosion and soiling in equipment.

- Definition of operating strategies to increase the TGV’s lifespan.

Engineering tool for steam turbine fouling monitoring

- Fouling rate calculation

- Determining times until next stop for maintenance and cleaning

- Identification of points likely to present accumulation of N2 and cumulative N2 calculation

- Evaluation of venting requirements based on their influence on downstream equipment

- Design and engineering of venting system

Thermal/hydraulic/mechanical design

Supplier selection

Supervision of manufacturer’s engineering documents

Manufacturer design review and recommendations

Workshop inspections

- Steam Generator (Kettle Type) (HTF/Steam)(SalTs/Steam)

- Steam Generator (Forced Circulation Type) (HTF/Steam)(Salts/Steam)

- Economizer (HTF/Vapor)(Salts/Vapor)

- Boronscope analysis

- Analysis of thickness measurements

- Sample analysis (analysis of elements and compounds)

Main results:

- Failure mechanism analysis: steaming, vaporization, corrosion, thermal shock, freezing, buckling, SCC, etc.

- Influence on thermal performance

- Influence on remaining life

- Proposal for monitoring and improvement measures

- Visual inspection

- Measuring thicknesses

- Identification of areas with widespread corrosion and local corrosion using MRUT methodology

- Study DCS signals

- Thermal-structural analysis against normal operating conditions and thermal shocks

- Fatigue analysis

- Performing metallography and metallographic replicas

- Study of the operating logic of the tracing system.

- Chemical analysis of salts

- Corrosion analysis. Sample analysis (analysis of elements and compounds)

Main projects:

- Analysis of mechanisms and causes of failure: overheating associated with tracing, corrosion due to salt degradation effect.

- Proposal for monitoring and improvement measures

- Defining optimal control logic

- Definition of a predictive maintenance plan.

Root cause analysis to determine the breakage origin of ball joints. Definition of corrective measures and improvement proposals. Definition of predictive maintenance plan

- Plant inspection

- Assessment of fault record

- Standard definition of failure

- Operating data analysis according to DCS

- Thermal-structural simulation of the solar collector, ball joint system and receptor tubes

- Assessment against fatigue and thermal shocks

- Analysis of the detail of the kneecaps and simulation process of blocking them

Root cause analysis to determine the breaking origin of the receptor tubes

- Plant inspection

- Assessment of fault record

- Standard definition of failure

- Operating data analysis according to DCS

- Thermal-structural simulation of the solar collector, receiver tubes and ball joints system

- Assessment against fatigue and thermal shocks

- Vacuum loss assessment in tubes

- Radiation effect assessment

Root cause analysis to determine the origin of shoes breakage and cross over deformations

- Plant inspection

- Thermal-structural analysis of the solar collector and cross over system

- Evaluation of the malfunction of the shoes and ball joint system

- Thermal shock effect assessment and fatigue analysis

- Evaluation of large cross over system deformations