Heat exchanger equipment

Direct Fired Heaters – Furnaces – Boilers (API560/ASME I/ASME IV) for monophasic/multiphasic processes:

HTF boilers, superheated water boilers, water bath boilers, crude heaters, refinery furnaces (convective+radiant sections), vis-breakers, saturated steam firetubed boilers, saturated steam watertubed boilers, fluidized bed combustion boilers

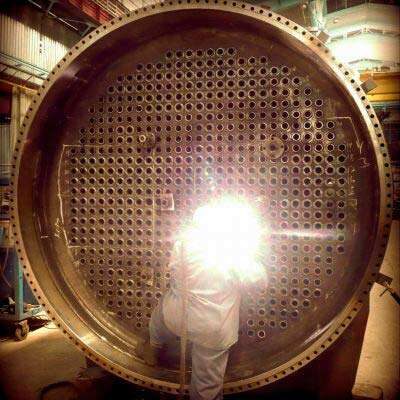

Shell and tube heat exchangers (TEMA/API 660) for monophasic/multiphasic processes:

Gas coolers, water coolers, compressor inter-coolers, recuperators, superheaters, reheaters, economizers, evaporators, condensers, LP-HP feedwater heaters, etc.

Air Cooled Heat Exchanger (API 661) forced or induced draft for monophasic/multiphasic processes:

Gas coolers, water coolers, oil-coolers, condensers, etc.

Cross-flow heat exchangers (finned tubes and cross-flow gas) for monophasic/multiphasic processes:

Recuperators/economizers, air preheaters, multi-effect evaporators, condensers, etc.

Direct contact heat exchangers for monophasic/multiphasic processes:

Deareators, degassers, cooling towers, exhaust gas heat recuperator (packed bed condenser), evaporative condensers, etc.

Cooling and heating of vessels/tanks (internal/external):

Jacketed vessels, suction heaters for viscous fluids, coils (agitation/non agitation).