CADE delivers full design and engineering services for heat transfer and process equipment and other units in oil&power industries by playing a role of technology and engineering partner for manufacturing companies, EPC contractors and plant owners.

CADE goes along with manufacturing and plant owner companies by providing in-depth expertise and technical support along both bidding and construction stages.

Engineering and design services range from process, thermal, hydraulic and detailed mechanical design, to procurement, commissioning and process performance advisory:

HTF boilers, superheated water boilers, water bath boilers, crude heaters, refinery furnaces (convective+radiant sections), vis-breakers, saturated steam firetubed boilers, saturated steam watertubed boilers, fluidized bed combustion boilers

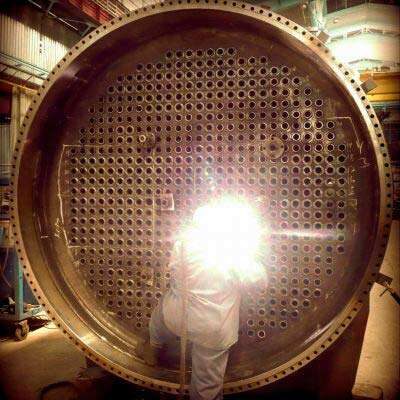

Gas coolers, water coolers, compressor inter-coolers, recuperators, superheaters, reheaters, economizers, evaporators, condensers, LP-HP feedwater heaters, etc.

Gas coolers, water coolers, oil-coolers, condensers, etc.

Recuperators/economizers, air preheaters, multi-effect evaporators, condensers, etc.

Deareators, degassers, cooling towers, exhaust gas heat recuperator (packed bed condenser), evaporative condensers, etc.

Jacketed vessels, suction heaters for viscous fluids, coils (agitation/non agitation).

CADE delivers full engineering and proprietary design of process units and plants including detailed design of main equipment around the following technologies.

Seeking engineering and consulting services? Tell us about your project on the following form and one of our specialists will reach out to you as soon as possible.

Also, you can call +34 967 19 01 72 or send an email to cade@cadesoluciones.com.

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

If you please, contact us and tell us about your project to inform you what we can do for you

We inform you about our engineering solutions