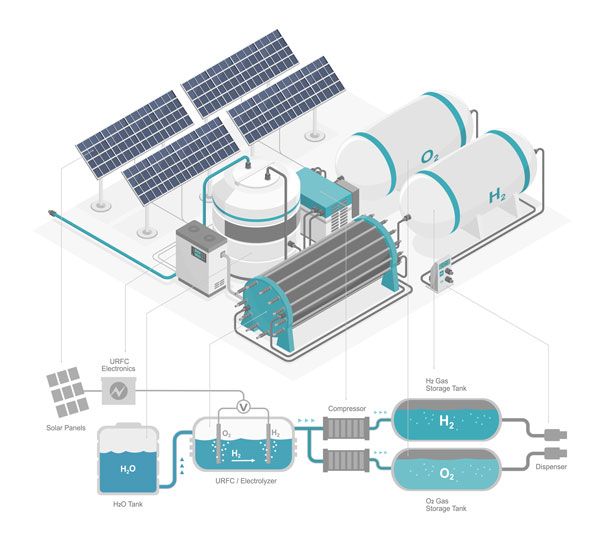

Green hydrogen, produced by electrolysis of water, is a promising option for the transition to a more sustainable and decarbonised energy economy. In this process, electricity, ideally obtained from renewable sources such as solar photovoltaics, is used to break down water (H2O) into hydrogen (H2) and oxygen (O2). This hydrogen is called “green” because its production does not generate carbon emissions, unlike “grey” hydrogen, which is produced from hydrocarbons and emits CO2.

Factors influencing the cost of green H2

Currently, the production cost of green H2 generated using renewable energy sources is around €8/kg2,3, which is significantly higher than that of H2 produced from natural gas, whose cost ranges from €1-2/kg2. The main factors that explain this difference in production cost are:

- Cost of Electricity: Most of the cost of green H2 comes from the electricity used in electrolysis. Making electricity from renewable sources cheaper is crucial to reducing the cost of green H2.

- Electrolysis Efficiency: Improving the efficiency of electrolyzers can reduce the amount of electricity needed to produce a given amount of H2.

- Economies of Scale: As electrolysis technology and green H2 production facilities expand, costs could decrease due to economies of scale

It is therefore necessary to explore strategies to reduce the cost of green H2 so that it can compete on costs with the so-called grey hydrogen. In the medium term, the strategies to be followed are:

- Technological Innovations: Advances in electrolyzer technology, such as the development of more efficient and durable materials, or the promising Solid Oxide Electrolyzer Cells (SOEC), can improve efficiency and reduce production costs.

- Renewable Energy Infrastructure: Expanding and improving infrastructure for renewable energy generation can provide cheaper and more abundant electricity for green H2 production.

Making the most of green O2

However, there is an easily manageable short-term strategy. The O2 generated as a by-product of the electrolysis itself can be used in various industries, such as healthcare, metallurgical and chemical. Currently, O2 is mainly obtained by cryogenic distillation, requiring up to 0.8 KWh for every kg of O2 produced1. The use of the O2 produced during electrolysis could generate extra income – between €0.10 and €0.40/kg – which would cushion the high costs of producing green H2. At the same time, it would make a significant contribution to lower global energy demand, contributing significantly to meeting decarbonisation targets.

In conclusion, Green H2 represents a key opportunity to move towards a sustainable and decarbonised energy system. Although it is currently more expensive than grey H2, technological improvements, infrastructure expansion and the use of oxygen as a by-product can contribute significantly to reducing costs and making green H2 a more competitive and efficient alternative.

CADE: Leader in Renewable Energy and Decarbonization

CADE stands out for its extensive experience in engineering projects for the generation of renewable energy, including photovoltaic and solar thermal plants, essential for producing green H2 and O2.

We offer technical and economic feasibility studies for decarbonization projects, evaluating costs, identifying optimization opportunities and planning the implementation of advanced technologies. Our ability to provide end-to-end solutions, from initial consulting to full project management, ensures efficiency and budget adherence at every phase.

Our focus on sustainability and decarbonization aligns our projects with global goals to reduce emissions and promote clean energy. This dedication is reflected in our innovative and efficient solutions in renewable energy and sustainable technologies.

With a solid track record in engineering projects, CADE is positioned as a key player in the renewable energy industry, prepared to face challenges and take advantage of opportunities in this emerging field.

Further information:

For any question or further information request about our services and technologies, please complete the following form: