Process CSP

processCSP

Industrial solar thermal energy

Tailor-made solutions for the integration of solar thermal in industry

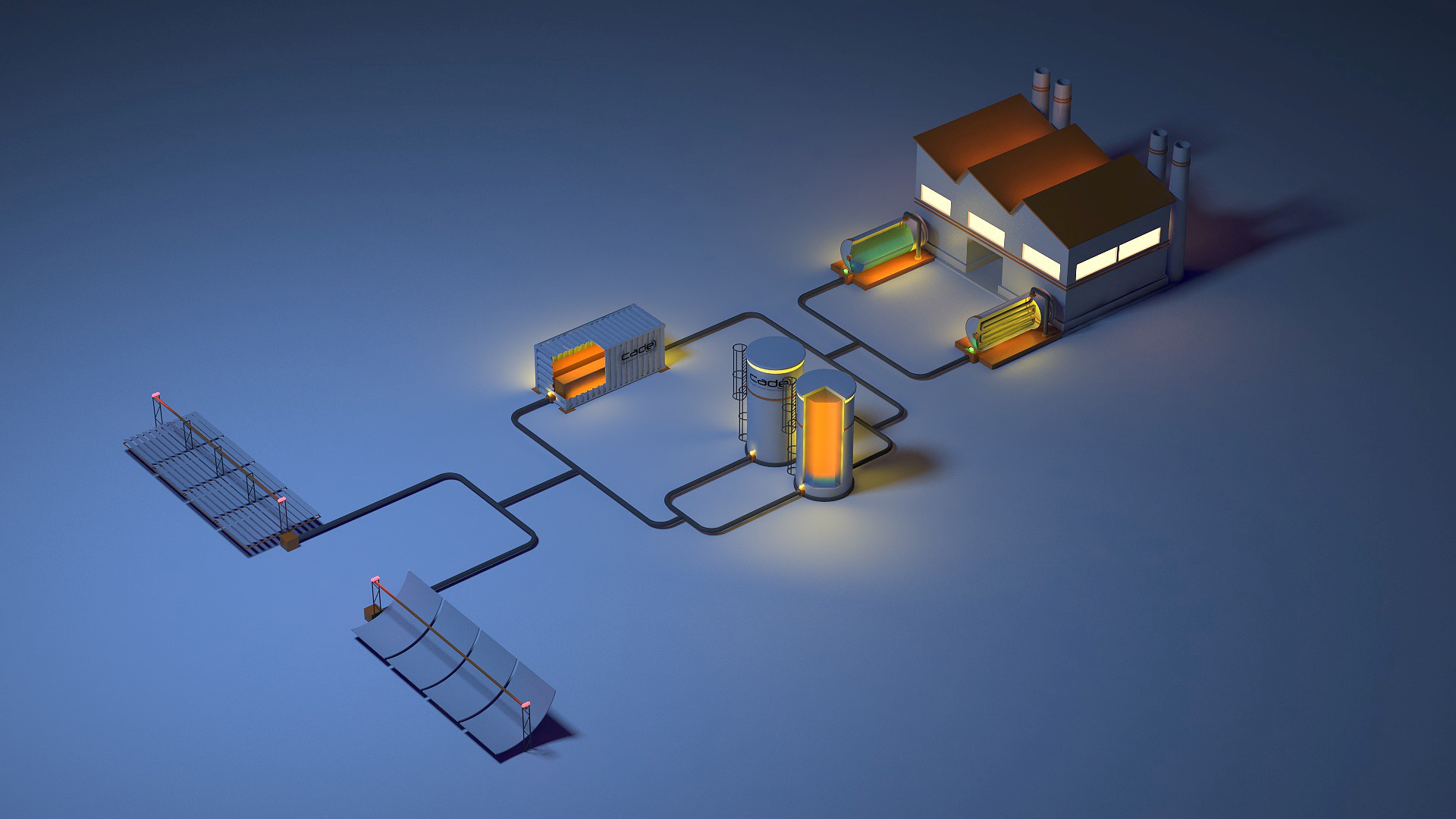

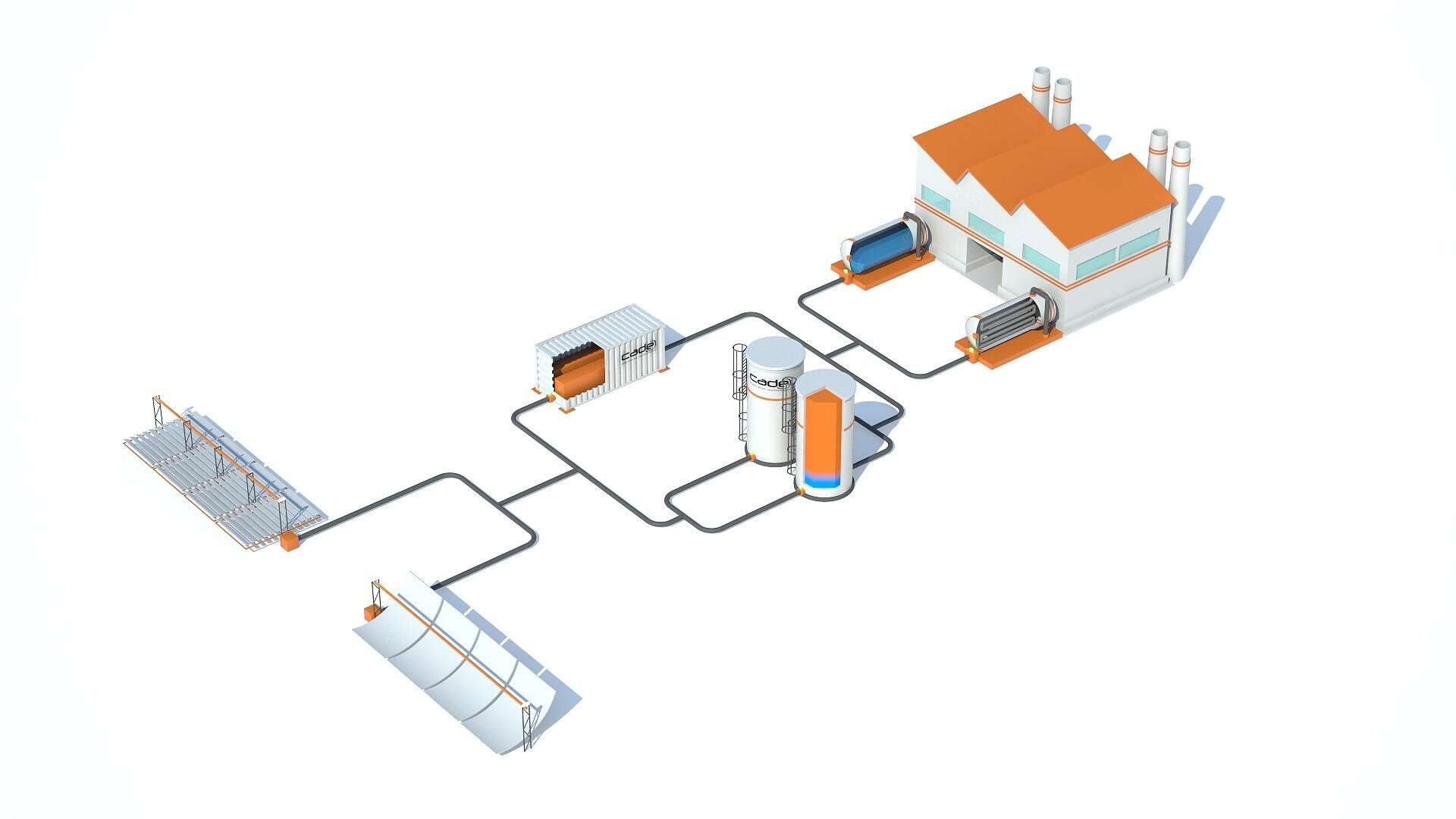

Industrial solar thermal energy consists in the use of concentrated solar energy with high performance for high and medium temperature heat applications (400ºC-150ºC), using thermal fluids commonly used in industrial processes (thermal oil, steam, superheated water , air). It is a 100% renewable, storable and integrable technology in existing industrial processes.

Its thermal storage capacity (TES) makes it fully manageable (heat generation-demand adjustment), allows the heat input to the process to be made independent from the availability of the sun (even reaching 24/7), and increases the annual hours of renewable energy delivered to the process (percentage of solar coverage) reducing losses.

Energy cost

20 - 45 €/ MWh

Savings comparing to Fossil energy sources

> 30 %

Fresnel collectors

Direct solar radiation is reflected by tracking mirrors, generally flat, arranged in rows, with a single axis on a stationary receiver.

With this technology, the highest annual energy production per installed surface is achieved

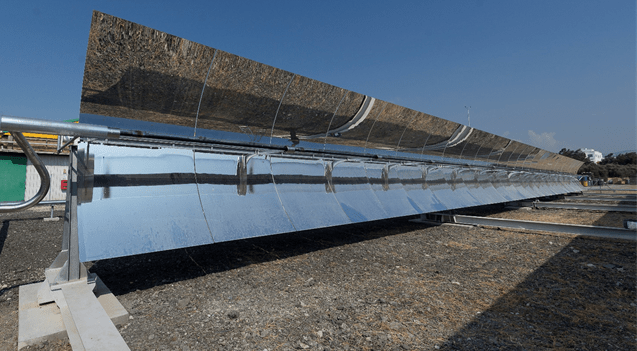

Parabolic trough collector (PTC)

Direct solar radiation is reflected by concave tracking mirrors, arranged in rows, with a single axis on a stationary receiver.

These CCPs present an optimized generation curve, maximizing generation during the first and last hours of the day.

SolidTES concrete storage

solidTES is a thermal storage system (TES), conceptually based on a set of tubes (through which a heat transfer fluid or HTF passes) embedded in a block of high heat capacity material, whose composition can vary depending on the required temperature . This system is capable of working with different types of HTF: molten salts, thermal oil, air, pressurized hot water or steam from both conventional and renewable sources.

Water Thermocline Tank

Thermal storage system based on the accumulation of sensible energy in water in liquid state. With a similar operation to that of domestic water accumulators, hot water is introduced through the upper part of the tank and cold water is extracted through the lower part. The hot water is kept in the upper part of the tank due to its lower density. The separation between the cold and hot part is obtained by means of a correct design of the tank. To keep the water in a liquid state, it is necessary for the system to operate at a pressure higher than the vapor pressure of the water corresponding to the working temperature.

Steam Generator/Separator

In the case that the thermal consumption of the industry is in the form of steam, in this system steam is generated under the conditions required by the industry.

Thermal oil or air Heater

When the thermal consumption of the industry is in the form of hot air or thermal oil, this heat exchanger is in charge of converting the energy captured from the sun into thermal energy that can be used by the industry.

Fresnel collectors

Direct solar radiation is reflected by tracking mirrors, generally flat, arranged in rows, with a single axis on a stationary receiver.

With this technology, the highest annual energy production per installed surface is achieved

Parabolic trough collector (PTC)

Direct solar radiation is reflected by concave tracking mirrors, arranged in rows, with a single axis on a stationary receiver.

These CCPs present an optimized generation curve, maximizing generation during the first and last hours of the day.

SolidTES concrete storage

solidTES is a thermal storage system (TES), conceptually based on a set of tubes (through which a heat transfer fluid or HTF passes) embedded in a block of high heat capacity material, whose composition can vary depending on the required temperature . This system is capable of working with different types of HTF: molten salts, thermal oil, air, pressurized hot water or steam from both conventional and renewable sources.

Water Thermocline Tank

Thermal storage system based on the accumulation of sensible energy in water in liquid state. With a similar operation to that of domestic water accumulators, hot water is introduced through the upper part of the tank and cold water is extracted through the lower part. The hot water is kept in the upper part of the tank due to its lower density. The separation between the cold and hot part is obtained by means of a correct design of the tank. To keep the water in a liquid state, it is necessary for the system to operate at a pressure higher than the vapor pressure of the water corresponding to the working temperature.

Steam Generator/Separator

In the case that the thermal consumption of the industry is in the form of steam, in this system steam is generated under the conditions required by the industry.

Thermal oil or air Heater

When the thermal consumption of the industry is in the form of hot air or thermal oil, this heat exchanger is in charge of converting the energy captured from the sun into thermal energy that can be used by the industry.

* Hover over the points to see more information about each of the elements

ProcessCSP plant configuration options with thermal storage

Advantages of processCSP

Manage your energy. Possibility to minimize sun availability?

Savings

Decarbonize while saving

Invest to maximize savings or save from day one with no initial investment

Savings vs other heat sources in the industry

Optimize your thermal generation operating costs using renewable solar thermal energy

Industrial solar thermal energy is already the most competitive source for heat generation in industry.

What we offer:

Business case study, turnkey solution or energy supply contract.

(*) Investment reference (CAPEX) and operating costs (OPEX), including fuel cost, for 10 years for heat generation of 4000-6000 MWh per year. Levelized cost (of energy in the form of heat (LCOH) in € / MWh calculated for 10 years of amortization of the installation, 3% discount rate and without considering additional advantages for the savings associated with the elimination of CO2 emissions, increase expected fuel price or public subsidies and that the useful life of the installation is 25 years.

The costs of thermal generation through renewable solar thermal energy have been drastically reduced in recent years, making industrial solar thermal energy already the most competitive source for the generation of heat in the industry.

The levelized cost per MWh of thermal generation, considering a payback period of 10 years, is half that of diesel and is practically the same as that of a minimum generation scenario using natural gas (€ 20 / MW h), without considering the cost of emissions or subsidies.

We offer tailor-made solutions of clean and competitive technology for the generation of heat in the industry

- Through consumer investment models and profit maximization

- Through energy sales contracts, in which it would not be necessary to face the investment.

Saving and decarbonisation

Minimize your thermal generation operating costs, saving CO2 emissions and taking advantage of available public aid

Increase savings even more when Carbon Emission Allowances and public funding are applied. Savings of more than 50% are achievable even compared to the tightest alternatives.

What we offer:

We also help you with the business case based on the available subsides.

(*) Investment reference (CAPEX) and operating costs (OPEX), including fuel cost, for 10 years for heat generation of 4000-6000 MWh per year. Levelized cost (of energy in the form of heat (LCOH) in € / MWh calculated for 10 years of amortization of the installation and 3% discount rate. The cost associated with CO2 emissions for fossil sources is included (€ 35 / ton) and the 40% reduction in the investment by public subsidies The additional advantage of the expected increase in fuel prices and that the useful life of the installation is 25 years is not considered.

Industrial solar thermal energy is already the most competitive source for the generation of heat in the industry. In addition to its cost reduction in recent years, we must add the cost savings of CO2 emissions and currently available public funding that apply to concentrating solar technology.

The levelized cost per MWh of thermal generation, considering a payback period of 10 years, and taking into account the cost savings of CO2 emissions and the subsidies applied, is 5 times lower than that of diesel and is practically the same half that of a scenario of minimum generation using natural gas (€ 20 / MWh)

Customized solutions of a clean and competitive technology are offered for the generation of heat in the industry, either with an investment model by the consumer and maximization of benefits or with a model of an energy sales contract in which it would not be necessary. face the investment and with the possibility of finding and managing the public subsides.

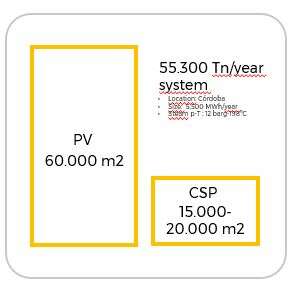

Saving vs photovoltaic

surpassing the best known solar technology: photovoltaic for industrial heat generation

Industrial solar thermal energy, due to its high performance to generate heat, requires between 3 and 4 times less space than photovoltaic. And it can be stored very effectively to deliver energy when there is no sun, even up to 24hx7d.

What we offer:

Generation of manageable thermal energy and with the best use of the available surface.

Genere calor para utilizar calor, la energía solar de concentración optimiza los costes energéticos al ser directamente utilizable en el proceso sin necesidad de conversión, a diferencia de lo que ocurría con la energía eléctrica de origen fotovoltaico

Generate heat to use heat, concentrating solar energy optimizes energy costs by being directly usable in the process without the need for conversion, unlike what happened with electrical energy of photovoltaic origin

Get the most out of your land. With equal space used, concentrating solar energy can obtain between 3 and 4 times more than the thermal energy that would be obtained with photovoltaic energy.

Solar thermal technology is the one that offers the highest energy yield per unit of occupied space of all solar exploitation technologies, making it the most economical source of clean energy that makes the best use of space for heat generation in the industry

*Pasa por encima de los puntos para ver más información sobre cada uno de los elementos

Industrial solar thermal is more manageable thanks to thermal storage

Thermal storage (TES) facilitates integration with your thermal process, achieving the adjustment of the renewable thermal generation curves and the process demand, maximizing the share of renewable solar energy penetration into the process and reducing losses.

What we offer:

Business case study, turnkey solution or energy supply contract including the most efficient alternative for thermal storage (SolidTES own technologies, pressurized water tanks, thermocline)

The thermal storage (TES) allows to minimize the waste of the solar resource excess of produced thermosolar energy. In an installation with TES, annual energy uses of over 80% can easily be achieved.

The thermal storage system is of special interest when you want to obtain a high% coverage of the total demand (> 40%) by means of solar energy, by adapting the generation curve to the demand curve of the installation.

We offer the study of the type and capacity of the best storage system for each case, designing and supplying storage systems in pressurized water for facilities in which temperatures are below 180ºC and in solid materials for high temperature applications between 180ºC and 400 ° C.

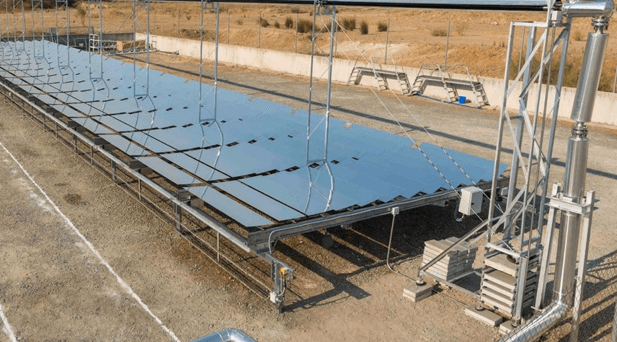

Solar concentrating collectors Fresnel technology

Fresnel technology

Direct solar radiation is reflected by tracking mirrors, generally flat, arranged in rows, with a single axis on a stationary receiver.

With this technology, the highest annual energy production per installed area is achieved.

Parabolic trough collector (PTC)

Direct solar radiation is reflected by concave tracking mirrors, arranged in rows, with a single axis on a stationary receiver.

These PTCs present an optimized generation curve, maximizing generation during the first and last hours of the day.

Both technologies use highly efficient vacuum absorber tubes as a receiver, where heat is collected and distributed by means of a heat transfer fluid.

Virtual tour of the plant

24 hour operating sequence

Proyect Editor Cyprus

In continious opeation since 2018

The EDITOR CSP (concentrated solar plant), and Solid-TES (concrete thermal storage), have been continuously delivering process steam, since it was build, to KEAN Soft Drinks’ factory in Limassol (Cyprus). Automatic operation of the system for the steam production mode is also achieved.

This is the first plant of its class in the Island of Cyprus which construction was finished on September, 2018.

Cyprus is an excellent location for process heat production by means of solar energy, due to its outstanding solar resources and the elevated cost of conventional fossil-fuels’ logistics to the island.