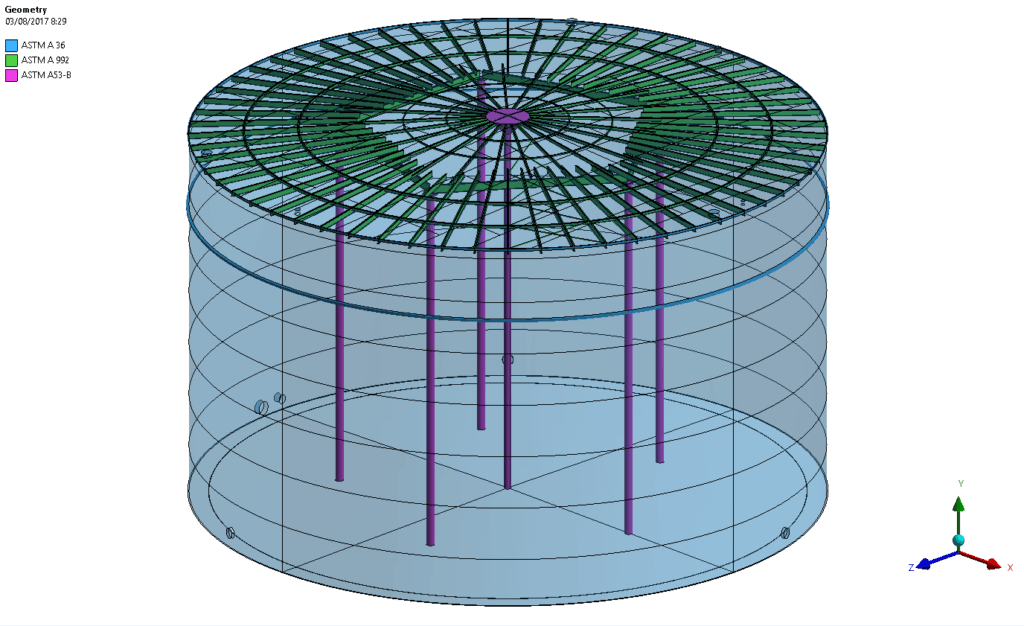

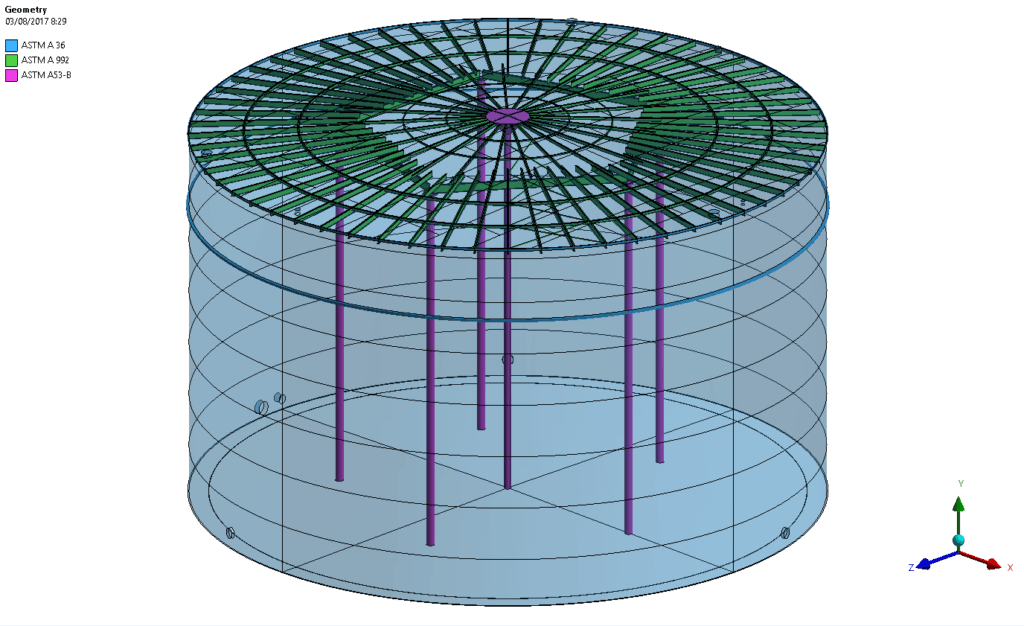

APPLICATION OF API 653 CODE TO APPROACH MODIFICATIONS ON EXISTING ATMOSPHERIC STORAGE TANKS

Table of Contents API-653 SCOPE API 653 “Tank inspection, repair, alteration, and reconstruction” standard covers

Table of Contents API-653 SCOPE API 653 “Tank inspection, repair, alteration, and reconstruction” standard covers

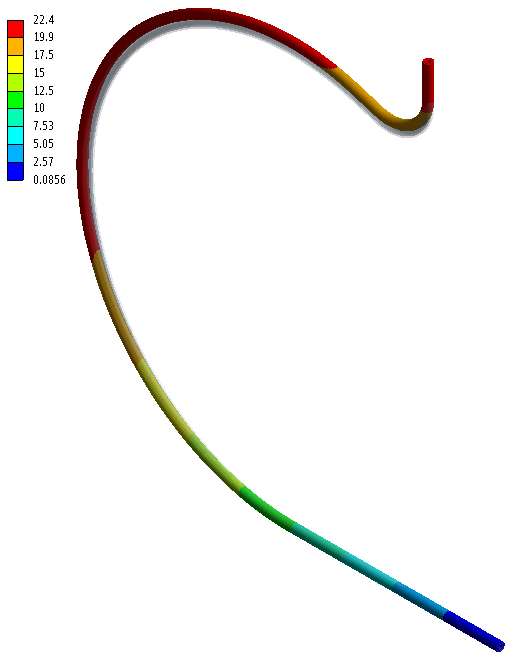

Objective An equipment manufacturer required CADE to conduct the validation design of a flexible pipe

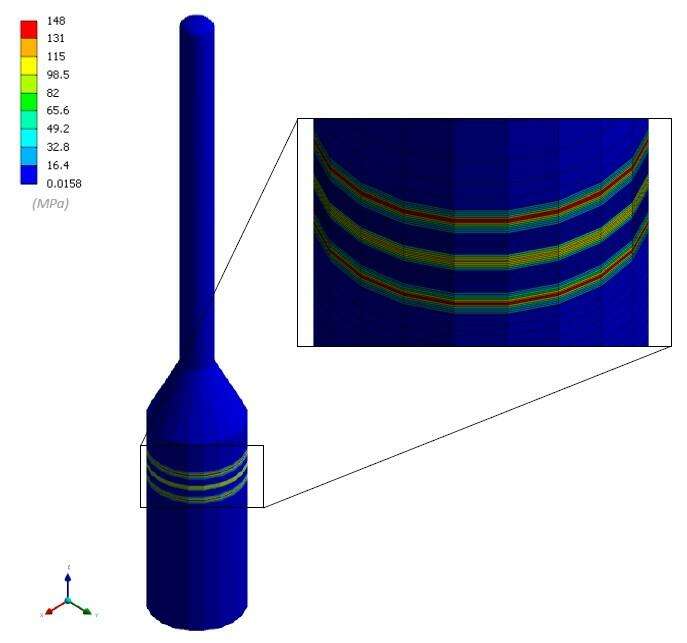

STRUCTURAL INTEGRITY ASSESSMENT DURING LOCAL PWHT Post weld heat treatment (PWHT) is a thermal treatment usually performed in steels that have

3D POINT CLOUD GENERATION TO MODIFY EXISTING SYSTEMS OBJECTIVE In projects for the modification or

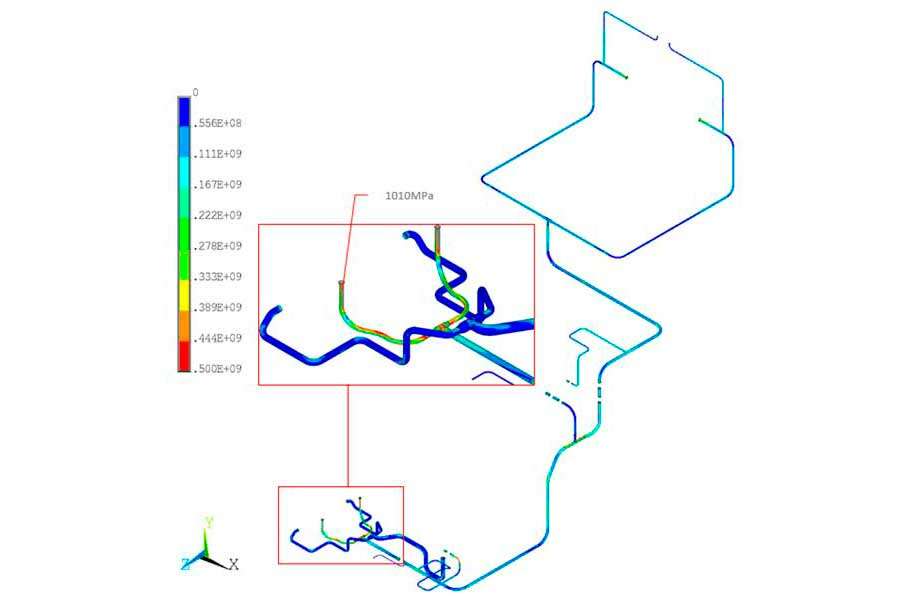

PIPING STRESS ANALYSIS AND FINITE ELEMENT ANALYSIS (FEA) FOR CREEP ASSESSMENT The owner of a

FATIGUE ANALYSIS OF PROCESS EQUIPMENT USING FINITE ELEMENT METHOD OBJECTIVE A significant supplier of process

Seeking engineering and consulting services? Tell us about your project on the following form and one of our specialists will reach out to you as soon as possible.

Also, you can call +34 967 19 01 72 or send an email to cade@cadesoluciones.com.

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

If you please, contact us and tell us about your project to inform you what we can do for you

We inform you about our engineering solutions