Risk-Based Inspection (RBI) methodology is a quantitative approach for establishing an inspection program using risk-based methods for static pressurized equipment, including pressure vessels, piping, tanks, pressure-relief devices (PRDs), and heat exchanger tube bundles, among others.

Content

Codes and standards

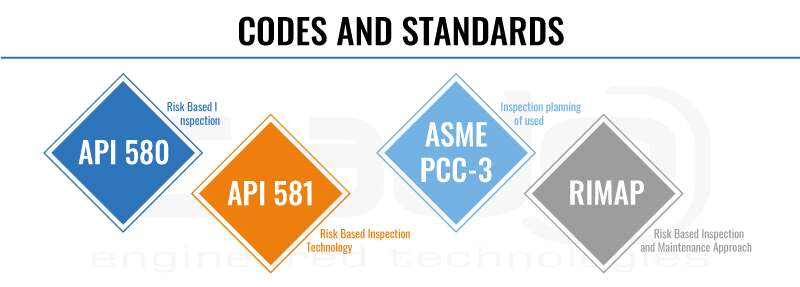

The following RBI international standards and codes are within the most relevant:

- API 580 – Risk Based Inspection, provides guidance for developing risk-based inspection (RBI) programs on fixed equipment in refining, petrochemical, chemical process plants, and oil and gas production facilities.

- API 581 – Risk Based Inspection Technology, provides quantitative procedures to establish an inspection program using risk-based methods for pressurized fixed equipment including pressure vessel, piping, tankage, pressure-relief devices (PRDs), and heat exchanger tube bundles.

- ASME PCC-3 – Inspection planning of used Risk-Based Methods, provides information on using risk analysis to develop and plan an effective inspection strategy. Inspection planning is a systematic process that begins with identification of facilities or equipment and culminates in an inspection plan. Both the probability of failure and the consequence of failure should be evaluated by considering all credible damage mechanisms that could be expected to affect the facilities or equipment.

- RIMAP- Risk Based Inspection and Maintenance Approach, is a European project that shall develop a unified approach for making risk-based decisions within inspection and maintenance. The focused industries are power, Petrochemical, chemical and Steel industries.

Determination of risk

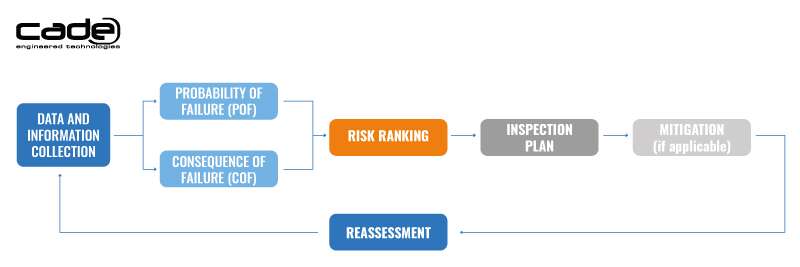

In general, the calculation of risk is determined by taking into consideration the following two critical factors:

- PROBABILITY OF FAILURE (POF). Defined as the chance that a particular asset to fail during a determined time and during its operations. This way, POF analyses every possible area where damage can occur and from where the entire project could be potentially compromised. POF is calculated for individual equipment by examining the potential damage mechanisms that it may be susceptible to

- CONSEQUENCE OF FAILURE (COF). It estimates failure consequences arising from faulty or damaged mechanisms or parts of a system. The purpose of COF is to categorize assets based on potential failure significance. These are categorized into three groups: health and safety impacts, environmental impacts, and business impacts.

Risk could be determined as a combination of these two factors according to following equation:

Risk = POF x COF

API 580 and API 581 gives quantitative values and information to determination of risk and its possible mitigation.

Risk assessment process

The following flow diagram indicates a general view of Risk Assessment Process:

Benefits of risk-based inspection

There are a lot of several benefits of a correct risk-based inspection program. The most important ones are as follows:

- Improving risk management by regular risk analysis assessments and its mitigation.

- Minimizing unexpected turn-off by preventing critical malfunctions.

- Saving money by deploying a more efficient inspection plan and reducing unplanned outages.

- Optimizing inspection and maintenance costs.

- Usage of inspection sources in a more economical way.

- Better visibility into the health of your critical assets.

- Reduction in the number of failures.

- Improvement in the reliability and efficiency of the equipment.

- Identification of operational modes associated with equipment degradation.

- Planning maintenance activities to avoid unexpected shutdowns and delays.

- Compliance of used equipment with the environment as well as safety regulations.

- Regular monitoring of equipment will lead to lesser technical malfunctions.

CADE experience on risk-based inspection and FFS codes

CADE, with a wealth of experience in design service for heat transfer, process, and static equipment, knows how to conduct a risk-based inspection program to evaluate pressure vessels, heat exchangers, reactors, columns, towers, tanks, and piping components.

Furthermore, should the need arise, CADE can provide solutions through Fitness for Service evaluations (ranging from Level 1 to Level 3 using finite element analysis in accordance with API 579-1/ASME FFS-1), as well as repair or replacement of pressure vessel and piping components.

With their expert engineering knowledge, skilled team, and strong business management, CADE is a leading independent engineering and consulting firm in the Oil & Power Industries.

Further information

For any query or request for additional information about our services and technologies, please complete the following form: