A new paradigm in wastewater sludge management: Towards zero sludge disposal by efficient and sustainable recovering of all value present in sludge. Sewage sludge (SS) no longer will be an issue, will be the main income of a WWTP (Wastewater Treatment Plant) instead, considering both economic and environmental perspective.

Sludge is a valuable resource and it has potential to become a water, energy and nutrient source, just transforming a conventional WWTP into a true circular economy factory by means of ZeroSD solution.

Secure, cost-effective and environmentally friendly sludge management system, Zero SD is based on our protected technology supercritical water gasification (SCWG), a high temperature and high-pressure hydrothermal process.

The SCWG (Super Critical Water Gasification) process consists of gasifying biomass waste in aqueous medium, under supercritical conditions. (Above its critical point which corresponds to a pressure of 22.1 MPa and a temperature of 374 ° C). At this operating conditions the water acquire particular properties (such as density, viscosity, thermal conductivity and specific heat) allowing the transformation of wet biomass in high calorific syngas through a clean process.

Biomass/organic waste is decomposed almost entirely in pressurized H2, CO, CH4 and CO2 by means of hydrolysis and oxidation reactions, a process favored by the high solubility in supercritical water of intermediate products. Intermediate inorganic salts are recovered through a selective precipitation process.

ZeroSD provides operational security to WWTP and SS producer, giving independence from external handling, future political and environmental concerns and tightening regulations.

Applicable to all kind of sewage sludge, primary, secondary or mixed, also including digestates, and every composition, local condition, circumstance or contaminant.

Either new construction of WWTPs or retrofitting facilities can take advantage of ZeroSD, a sustainable solution from both economic and environmental sides for wastewater treatment.

ZeroSD technology allows a reduction of the energy demand of 13 kWh/p.e. & year of the biological treatment (30%-40% total WWTP energy consumption) due to residence time reduction versus aerobic stabilization and air injection system boosting using the ZeroSD high pressure produced CO2.

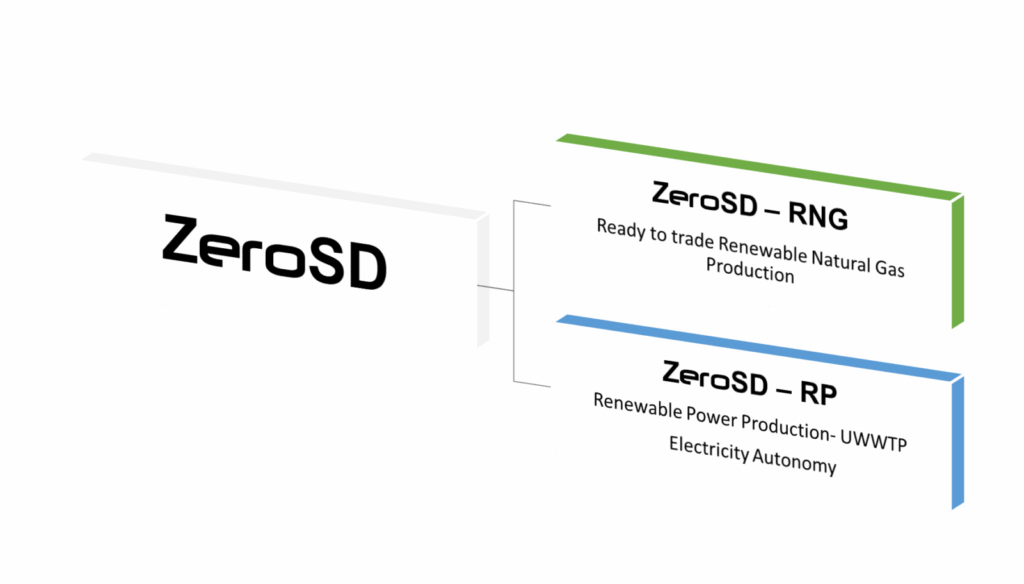

RNG configuration has the clear advantage than final gas quality obtained is a low cost high pressure, clean and purified renewable natural gas grade (bio-methane), allowing its direct use in NG grid injection, transport or other common NG uses. No additional compression is required. This is not technically nor economically feasible with other competing technologies as A.D. furthermore in the same WWTP size (10-50k P.E.).

RP configuration offers renewable power to WWTP as principal sludge valorization. The objective is to provide the larger electricity autonomy to the plant even in the WWTP size range of 10-50k P.E.

Based on the target specific energy demand subject to the treatment capacity, the simple microturbine set of the ZeroSD-RP configuration nearly provides electricity autonomy (85%-95%),

Optionally plug&play sets Organic Rankine Cycle run with available high temperature heat and produced water pressure energy recovery system achieve not only full and competitive energy autonomy but also electricity in excess to be injected in to the electricity grid.

Related articles

Follow us in our social networks

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – Spain

Av. Adeca, 55, 02007 Albacete - Spain

C/Raimundo Fernández Villaverde, 53 (Entreplanta), 28020 – Madrid

© Copyright 2003-2024 Cade Soluciones de Ingeniería S.L. - Terms and Conditions of Use

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

If you please, contact us and tell us about your project to inform you what we can do for you

We inform you about our engineering solutions