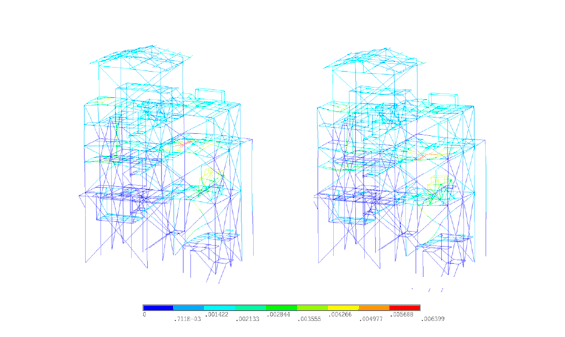

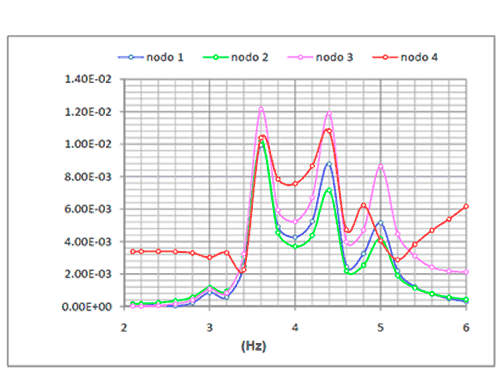

Industrial building structures in which dynamic process equipment is installed (Pumps, Compressors, Stirred Reactors / Tanks, Centrifugal Separators, Thin Film Evaporators, Coke Drum Towers, etc.) usually show large amplitude vibrations (even observable to the naked eye) that need to be corrected, or prevented, along design and engineering stages.

Abotu CADE Engineering:

CADE has more than 15 years of experience developing mechanical and industrial engineering projects. During this time, CADE has become a pioneer in the use of computer-aided engineering (CAE) applications and provides structural analysis, simulation modelling, engineering and consulting services, finite element analysis (FEA) and computational fluid dynamics (CFD) in different equipment, elements and structures.

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

Albacete

Parque Científico y Tecnológico

Paseo de la Innovación 3, 02006 Albacete – España

Tel. +34 967 19 01 72

C/Raimundo Fernández Villaverde, 53 (Entreplanta)

28020

Madrid – España

If you please, contact us and tell us about your project to inform you what we can do for you

We inform you about our engineering solutions